Navigating You into Space

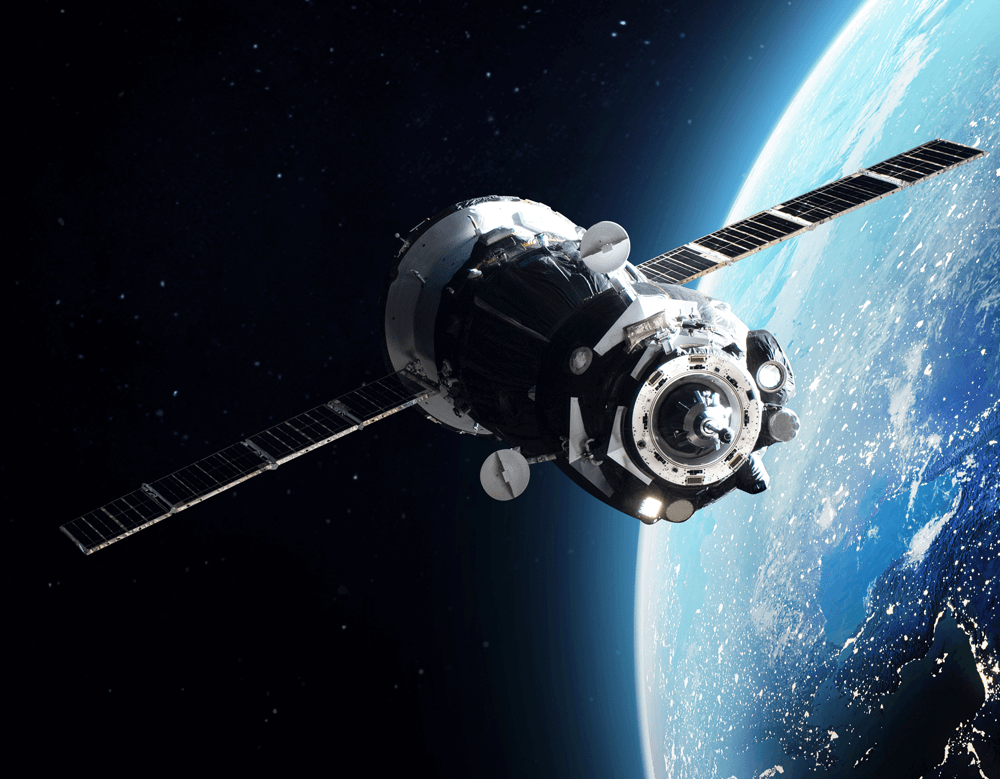

Space represents one of the most challenging frontiers for materials design: extreme temperatures, cosmic rays and ions, and more.

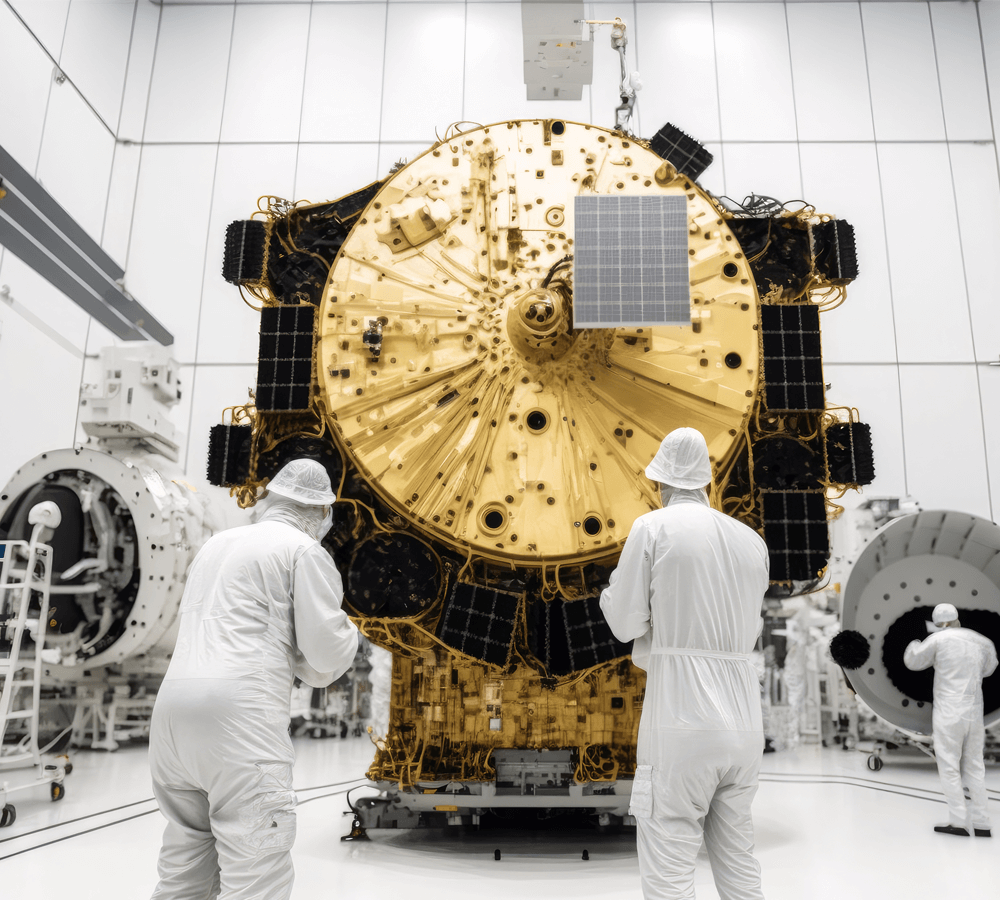

We work with a range of high profile global organizations and institutions supporting cutting edge space exploration initiatives, such as aerospace applications and satellite propulsion systems.

With over 170,000 advanced materials available, our expert Technical Solutions team of scientists and engineers offers you support for your product customization needs, quickly and professionally, to your specific requirements.

Goodfellow’s materials all meet the ISO 9001 standards and accreditation.

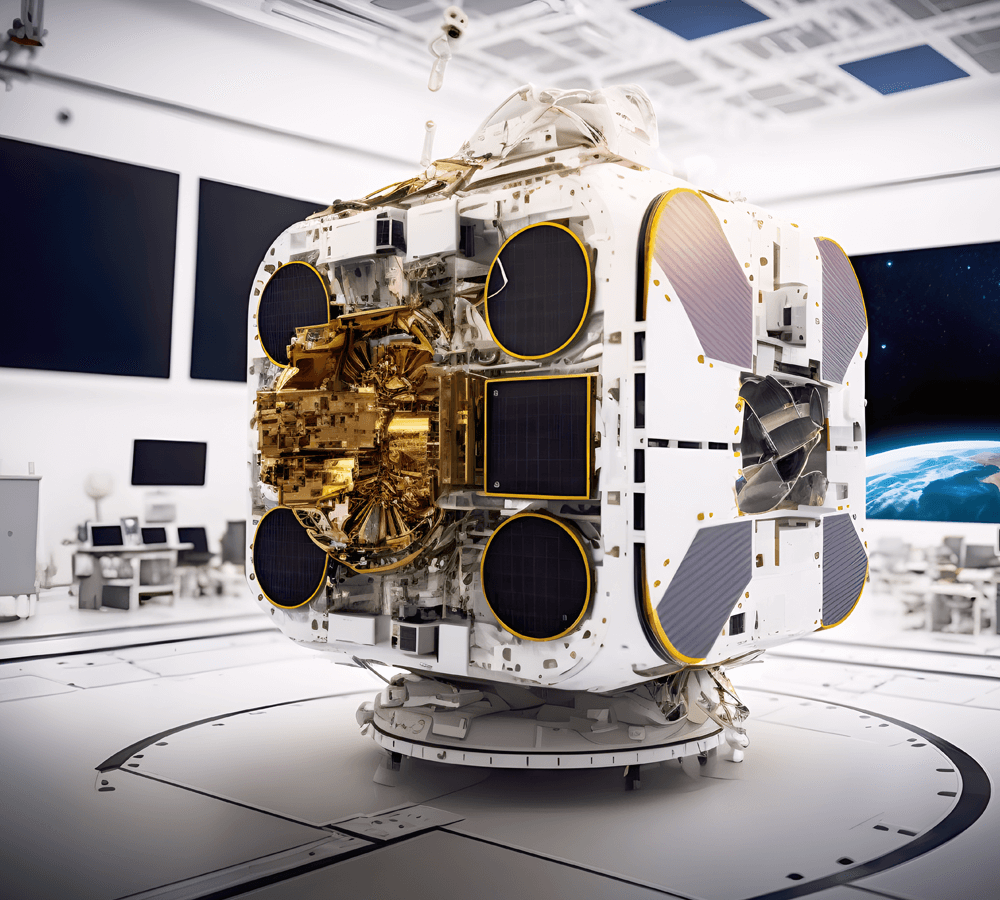

Optimal Materials for Satellite Propulsion

Using hot gasses and plasmas from either chemical or electrical processes to create the processes for satellite propulsion, requires your materials to take account of chemical and temperature resistance.

Ceramic materials are a material of choice for these applications as they are generally highly inert and resistant to very high temperatures. It is also possible to combine ceramics with polymers to create blended materials with improved material properties, such as better strength-to-weight ratios and durability.

In addition we supply a broad range of our customers with refractory metals, such as molybdenum, niobium and tantalum, that have incredibly high hardness and wear properties. Their thermal stability and chemical resistivity can make excellent metal fasteners for satellite propulsion systems that have outstanding hardness and stress and strain resistance.

Our broad range of products can support your requirements.

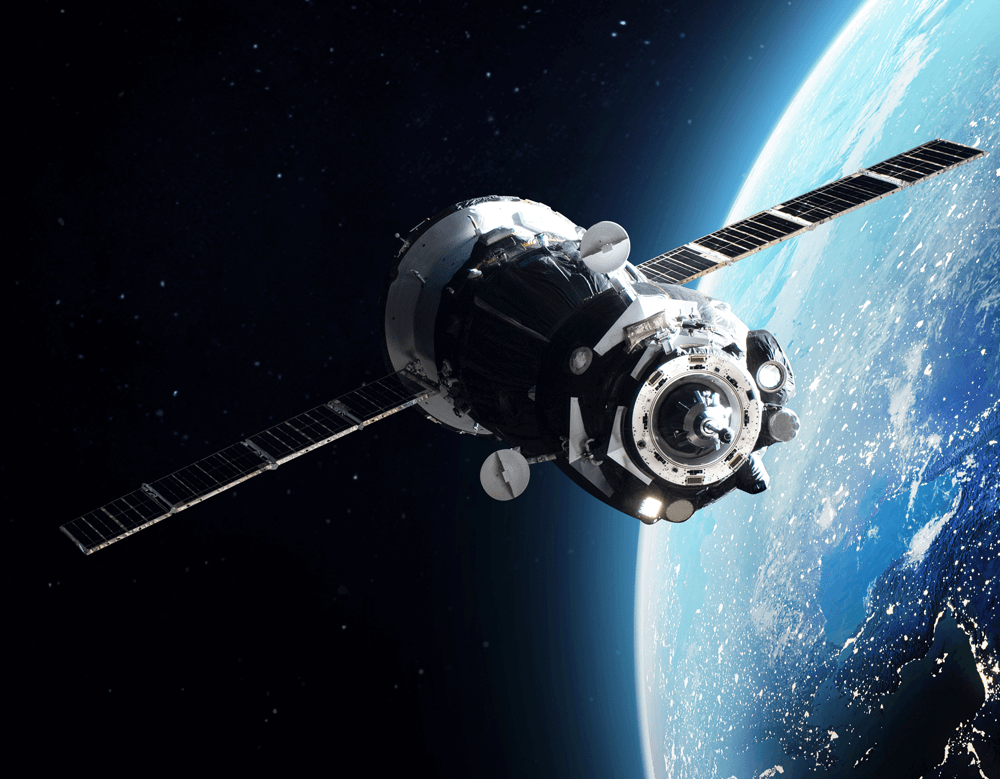

Optimal Materials for Space Technologies

Our customers have two products of choice for space technologies: Macor® and Kapton®.

Macor® is a ceramic-glass hybrid and an ideal material for harsh environments and high temperature applications, with excellent thermal insulator. It is also compatible with vacuum environments.

Its technical properties are close to that of a ceramic but with the machinability of a polymer, so it enables the creation of custom components, even with traditionally difficult to manufacture shapes.

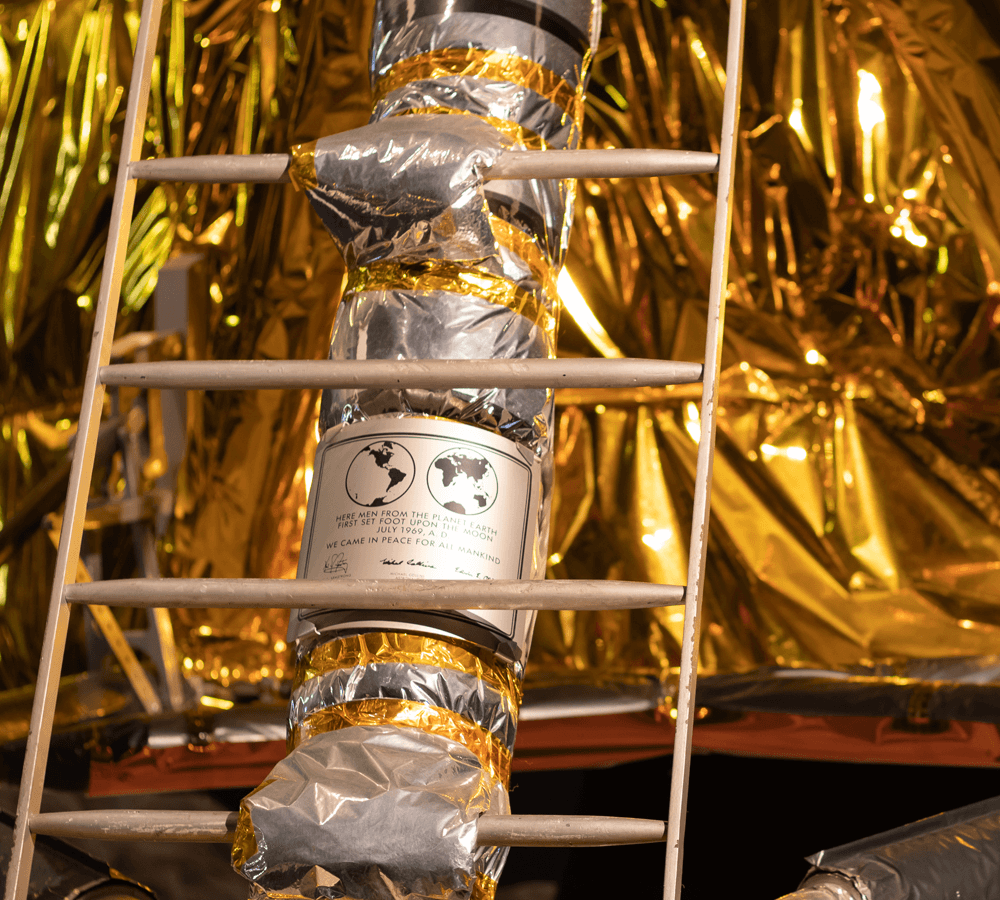

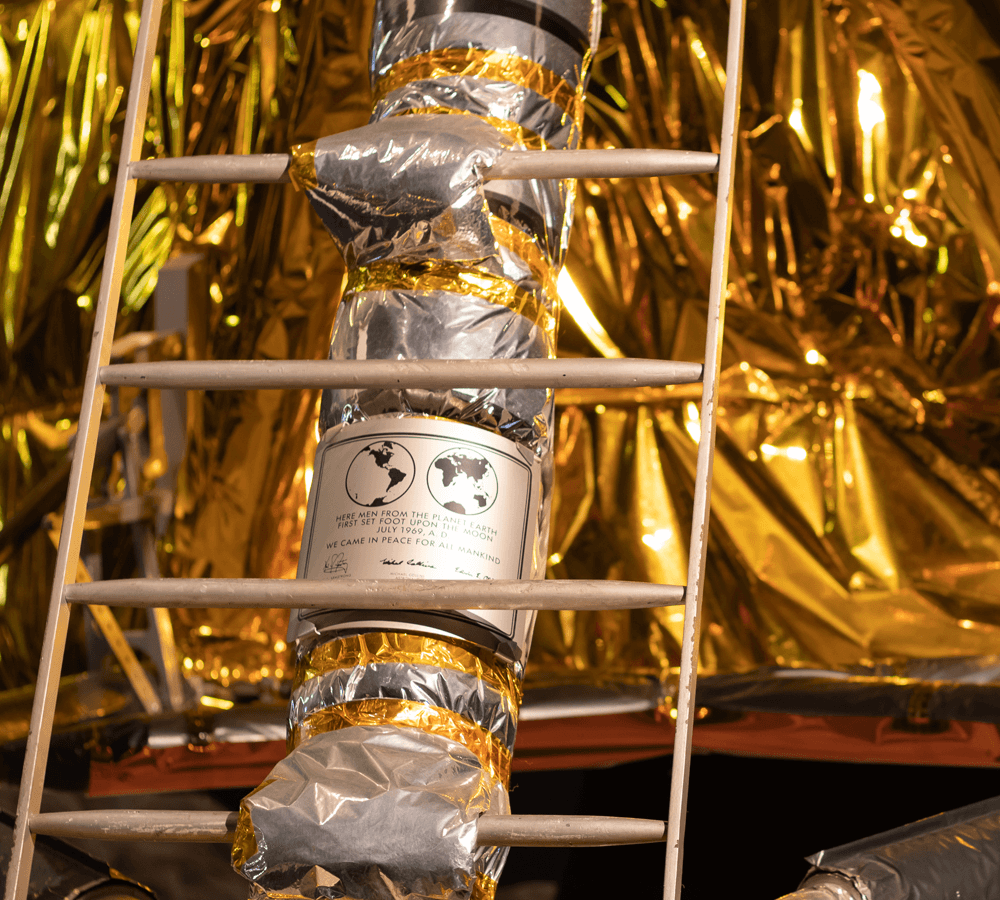

Kapton® is a great material for radiation resistance and vacuum compatibility, often manufactured as a film. It is frequently used in high vacuum chambers for wires and components insulation as it does not increase the base pressure in the instrumentation.

Other benefits include its heat-resistant of up to 400°C and it can be combined with other materials such as gold to create heat resistant blankets. We also see the application of Kapton® wrapped around or used to cover regions of hardware and instrumentation.

Our Product Range

At Goodfellow, we offer a comprehensive range of high-purity materials relevant to your applications, including:

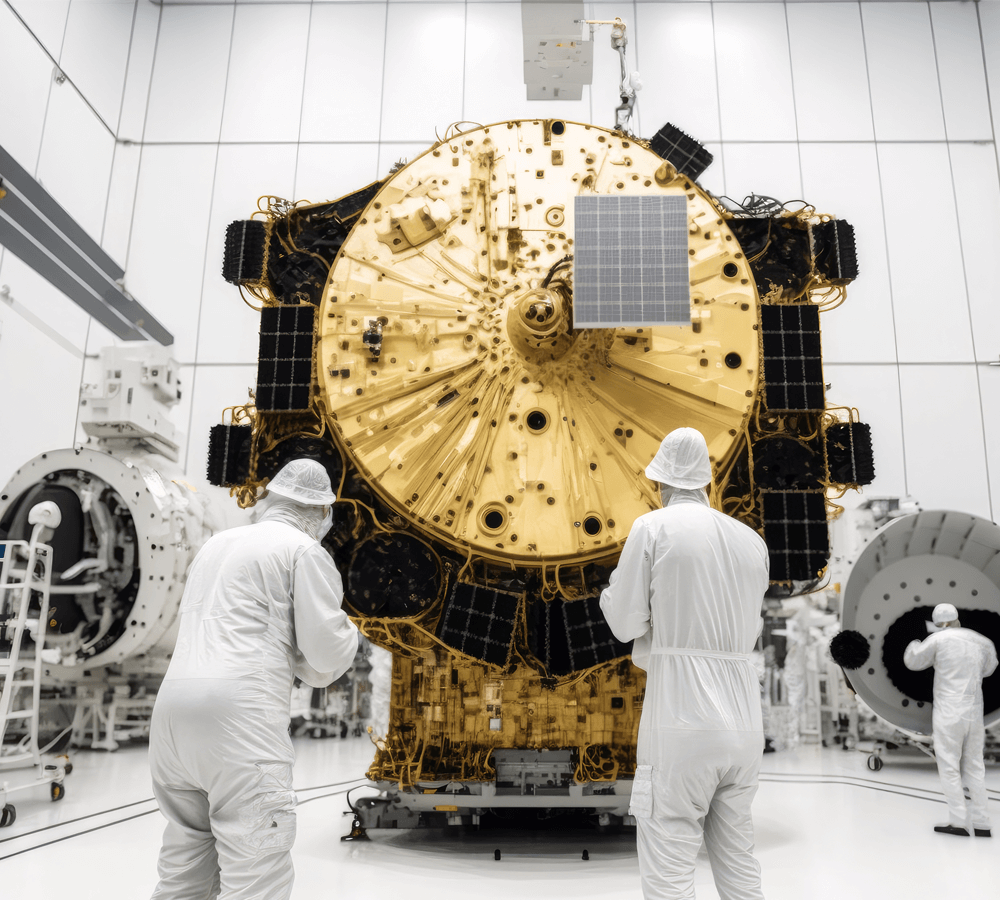

Understanding Refractory Metals

Refractory metals are another class of materials that can be found in satellite propulsion systems. Refractory metals, which includes metals such as molybdenum, niobium and tantalum, have incredibly high hardness and wear properties.

The thermal stability and chemical resistivity of refractory metals makes refractory metals well-suited for use in satellite propulsion systems and other space tech applications.

However, one of the challenges is that many of the components in satellite propulsion systems may need more complex machining and this can somewhat be more difficult with these very hard metals.

With the right expertise though, refractory materials can make excellent metal fasteners for satellite propulsion systems that have outstanding hardness and stress and strain resistance.

For mission-critical satellite propulsion components, with the low thermal expansion and creep of these materials, you can be confident in the reliability of these pieces.

What's New