Supporting Your Challenges

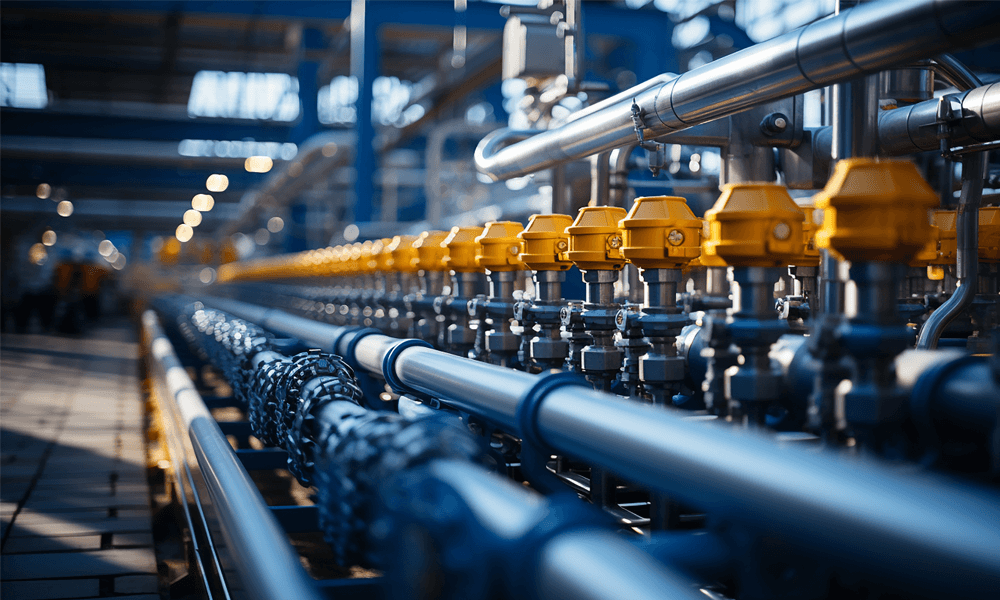

The oil and gas sector uses a diverse range of materials for the construction of extraction plants, the transport of fuels, and also in refinement centers.

We understand the impact of chemical corrosion on materials and the need for temperature resistance and the ability to withstand high pressures.

The team here at Goodfellow is here to support you with the supply of our 170,000 advanced materials and product customization services.

Steel - is it a Viable Material?

Steel is still one of the most widely used materials in the oil and gas industry due to its strength, machinability, and durability, but standard steels have limited chemical resistivity.

Steel performance improves with the use of stainless steel to help prevent rusting from oxidation processes as well as chemical attacks. Alternatively, use a superhydrophobic coating to create a protective layer on the side of the steel that will ensure exposure to chemicals.

Some examples of superhydrophobic coatings include silver nanoparticles and also a variety of polymers, from polytetrafluoroethylene (PTFE) to polymers such as polyurethane. Polymer linings can be particularly useful as they can be sprayed or added to already-machined metal components to provide a protective layer.

Low-carbon steels or coatings of zinc oxide and copper oxides can be a useful way of creating self-cleaning steels. A large amount of carbon steel is still used for the manufacture of pipelines due to its reasonably low costs and its ability to add layers or coatings and it would be a cost-effective way of achieving good chemical protection without adding large amounts of expense.

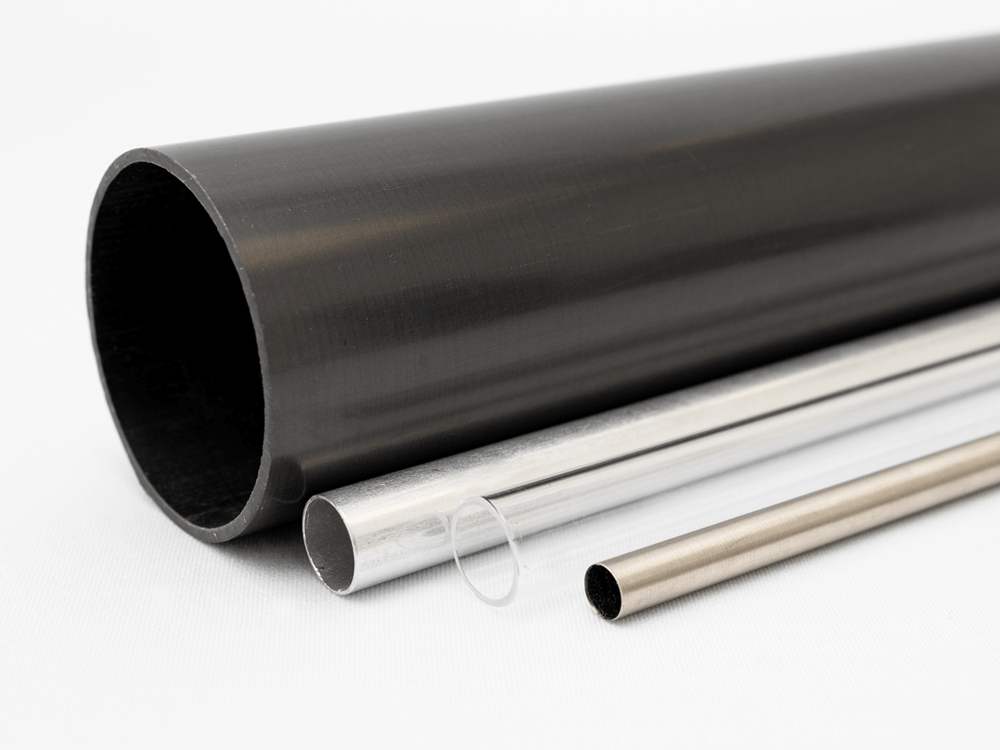

Our Product Range

At Goodfellow, we offer a comprehensive range of high-purity materials relevant to your applications, including:

Technical Solutions and Services

Goodfellow is a renowned international materials supplier with extensive expertise in crafting custom alloys and materials for numerous applications.

With 48-hour dispatch options on all in-stock off-the-shelf materials and a catalog of over 170,000 materials spanning low carbon steels to advanced polymer blends, Goodfellow can not only supply you with the right materials but provide you with the scientific and technical support to choose the most appropriate ones.

Polyurethanes and Polyethylene Terephthalate (PET)

Polyethylene Terephthalate (PET) has excellent gas barrier properties and resistance to mineral oils solvents and acids and could be another option to consider.

Patented Alloys including Fecralloy® and Monel®

Goodfellow supplies a number of patented alloys, such as Fecralloy® and Monel®, specifically designed to give outstanding corrosion resistance without sacrificing mechanical performance.

Beryllium Copper

This is one alloy that is already currently used on a number of gas rigs due to its explosion-resistant mechanical properties.

Tantalum

Options like tantalum, which has extremely high chemical resistance and is inert to acidic environments, may be a good choice for small components that require very low failure rates and will be exposed directly to crude oils, especially those with relatively high H2S concentrations.

Polymer Coatings (PTFE) and Inert Ceramics

Goodfellow also provides an extensive range of polymer coatings and inert ceramics. PTFE is available in a number of forms, including films and sheets, where coating or covering is the desired approach to chemical protection.

Coated on different substrates and supports, customized shapes can be produced in line with your technical drawings.

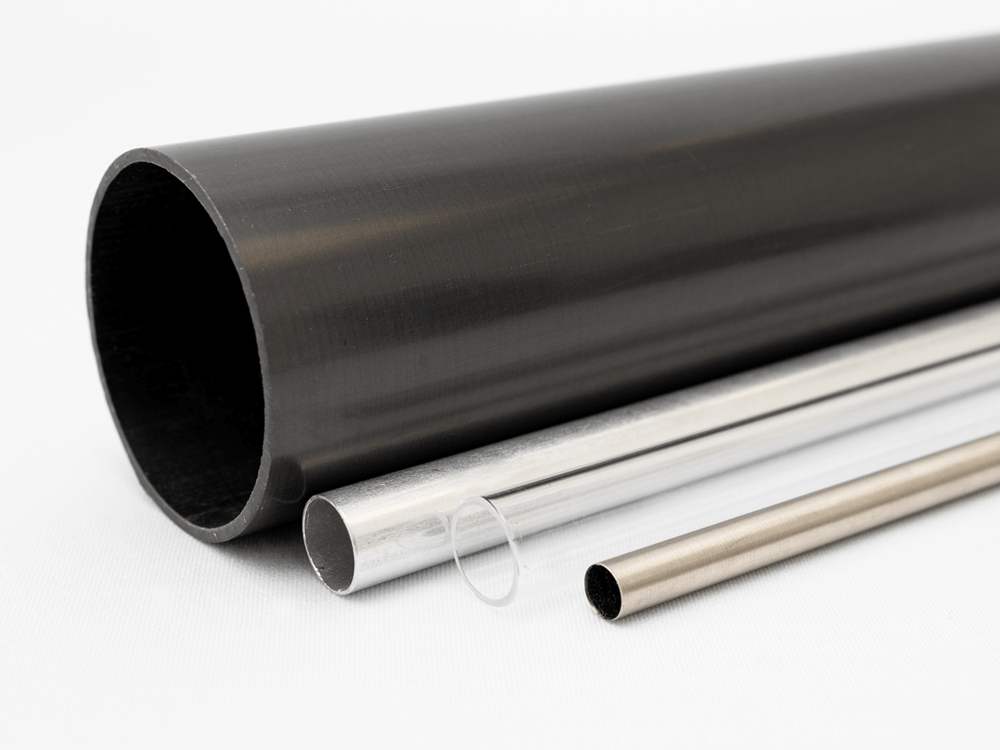

Stainless Steel

Our range of stainless steel products are available in a number of material forms, such as bars, rods and foils.

There are many options for standard thicknesses for the supplied steel foils and sheets, but if non-standard options are required, custom thicknesses are available upon request.

High-Purity Starting Materials and Metals

High-purity starting materials and metals are available for customers who wish to create their own custom protective materials, and Goodfellow is always happy to discuss making prototypes of custom blends to specific customer requirements.

High-purity and high-quality materials, and specially tailored alloys, can help improve the operating lifetime of components and minimize costs associated with maintenance and component failure.

What's New