Key Benefits of Additive Manufacturing Materials

Our diverse selection of materials are chosen for their suitability and outstanding qualities across metals, alloys, ceramics, and composites all available in a range of lengths and diameters, for delivery anywhere in the world.

Having access to Goodfellow's specialist materials allows you to:

- Create products with superior performance: The materials cater to applications requiring high strength, durability, or resistance to extreme conditions

- Explore innovative designs: The availability of novel materials like HEAs opens doors for groundbreaking product development in various sectors

- Tailor products to specific needs: The diverse material selection allows for choosing the best option based on the desired properties for the final product

There are numerous possibilities for the development and manipulation of materials, some of the advantages include:

- Design freedom: It enables the production of highly intricate and complex geometries that are not feasible with traditional manufacturing methods

- Minimal waste: Unlike subtractive manufacturing processes, where excess material is removed, additive manufacturing is a precise and efficient process that minimizes waste and so reduces costs and has a positive impact on the environment

- Customization: Enables personalized products tailored to individual needs and preferences. This level of customization opens up new opportunities in industries such as healthcare (e.g. patient-specific implants and prosthetics)

- Cost-effectiveness: It eliminates the need for costly tooling and reduces the time required for manufacturing. This makes it a cost-effective solution, particularly for low-volume production or rapid prototyping

Our Product Range

Our products are available in a range of quantities, lengths and diameters.

The advantage of choosing Goodfellow is that you will get the results you expect, want, and need, every time.

With our extensive range of high-quality and consistent materials, we can offer the exact tailored solution to your needs, unlocking the unlimited potential of additive manufacturing and 3D printing.

| Metals: stainless steels, titanium, aluminum, nickel and cobalt alloys | |

| Ceramics: alumina, zirconia, and titania | |

| Polymers: ABS, nylon, PEEK | |

| Waxes: ABS wax filaments, SLA resins and jetting waxes | |

| Resins: epoxy and acrylic resins, and polyurethane resins |

Associated Advanced Manufacturing Technologies

Advanced Manufacturing and 3D Printing is versatile and has a wide range of technologies that go beyond traditional manufacturing methods including:

Stereolithography (SLA)

To cure photopolymer resin layer by layer, producing high-resolution objects with intricate details

Selective Laser Sintering (SLS)

To selectively heat and fuse powdered material, creating durable parts with excellent mechanical properties

Fused Deposition Modeling (FDM)

Involves extruding thermoplastic filaments layer by layer to build up objects

Electron Beam Melting (EBM)

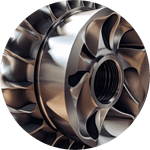

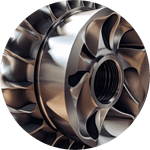

To melt and solidify metallic powders, to produce complex metal parts

Direct Metal Laser Sintering (DMLS)

To melt and fuse metal powders, to fabricate functional metal components with high accuracy

Digital Light Processing (DLP)

DLP to cure liquid resin layer by layer, offering high printing speeds and excellent surface quality

Applications

The applications of additive manufacturing span industries including aerospace, automotive, healthcare, and consumer products.

Let's explore some of the key use cases and industries that rely on Goodfellow’s advanced materials.

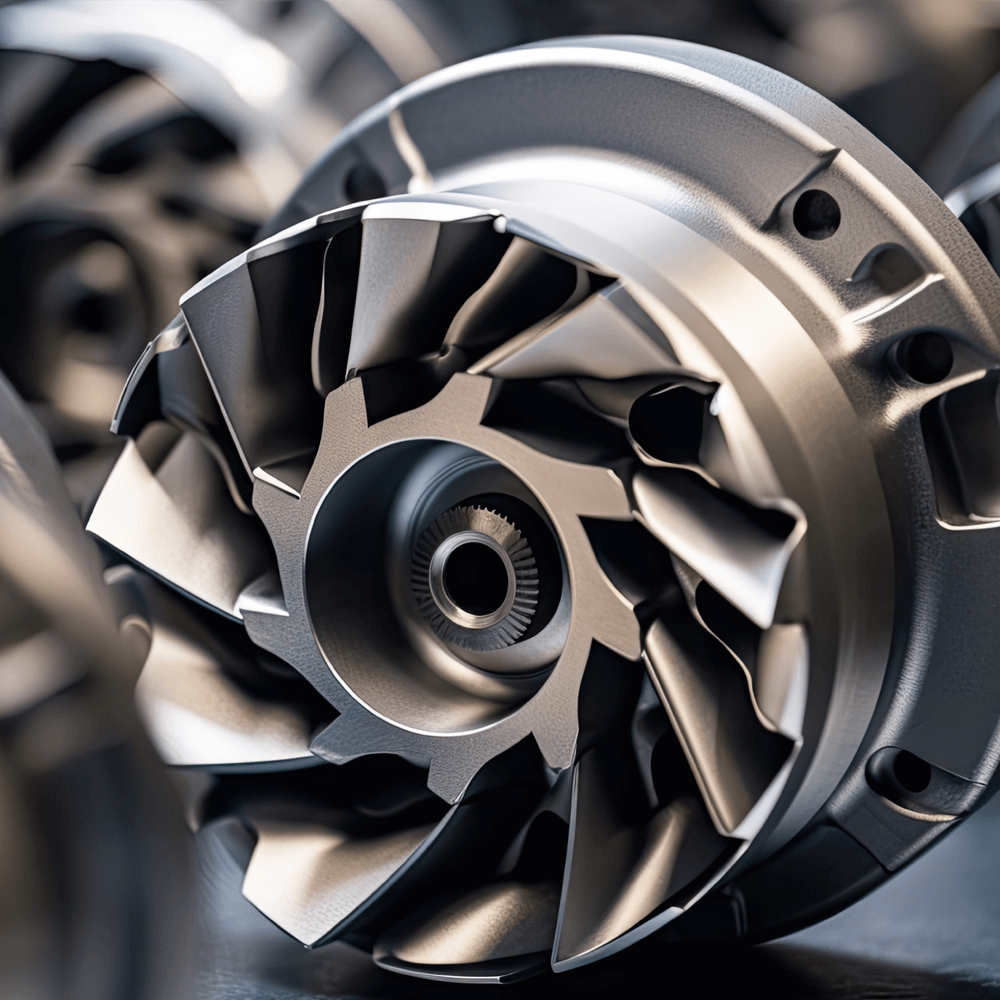

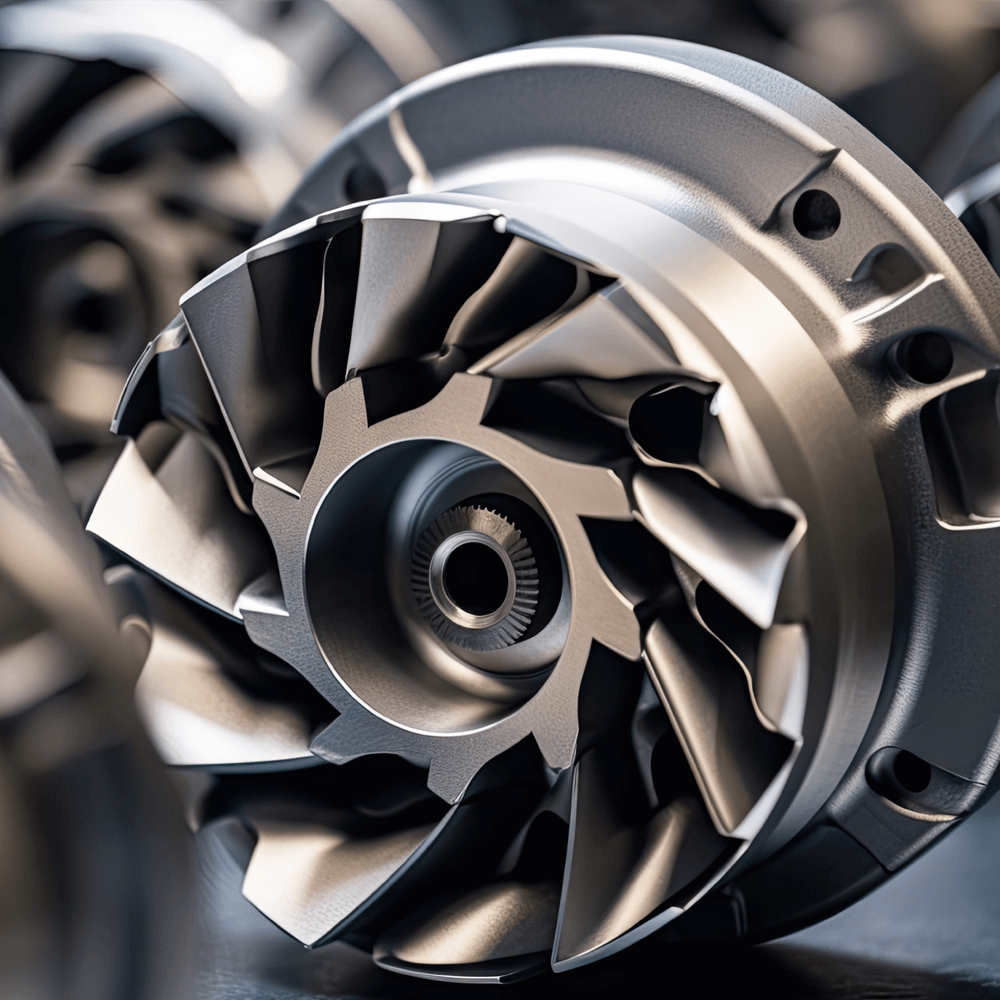

Aerospace

By utilizing advanced additive manufacturing materials and design optimization, engineers can create lightweight and high-performance parts that enhance fuel efficiency and reduce emissions. This technology also enables the rapid prototyping of new designs, allowing for faster iteration and development.

Automotive

Companies are leveraging this technology for both the prototyping and production of lightweight components, optimize designs, and improve vehicle performance. Additive manufacturing also enables the production of spare parts on-demand, reducing inventory costs and lead times.

Consumer Products

Additive manufacturing offers opportunities for customization and personalization. Companies can now create unique products that cater to individual customer preferences. From personalized jewelry to customized home decor, 3D printing is enabling a new era of consumer-centric production.

Healthcare

This technology is enabling innovation in Healthcare such as pacemakers, instruments, medical devices, X-Ray filters, moisture and anticorrosion barriers, biocompatible substrates, packaging material, radiotherapy linings, medical imaging, MRI shielding, electrodes in medical devices, implants, tissue regeneration substrates.

What's New