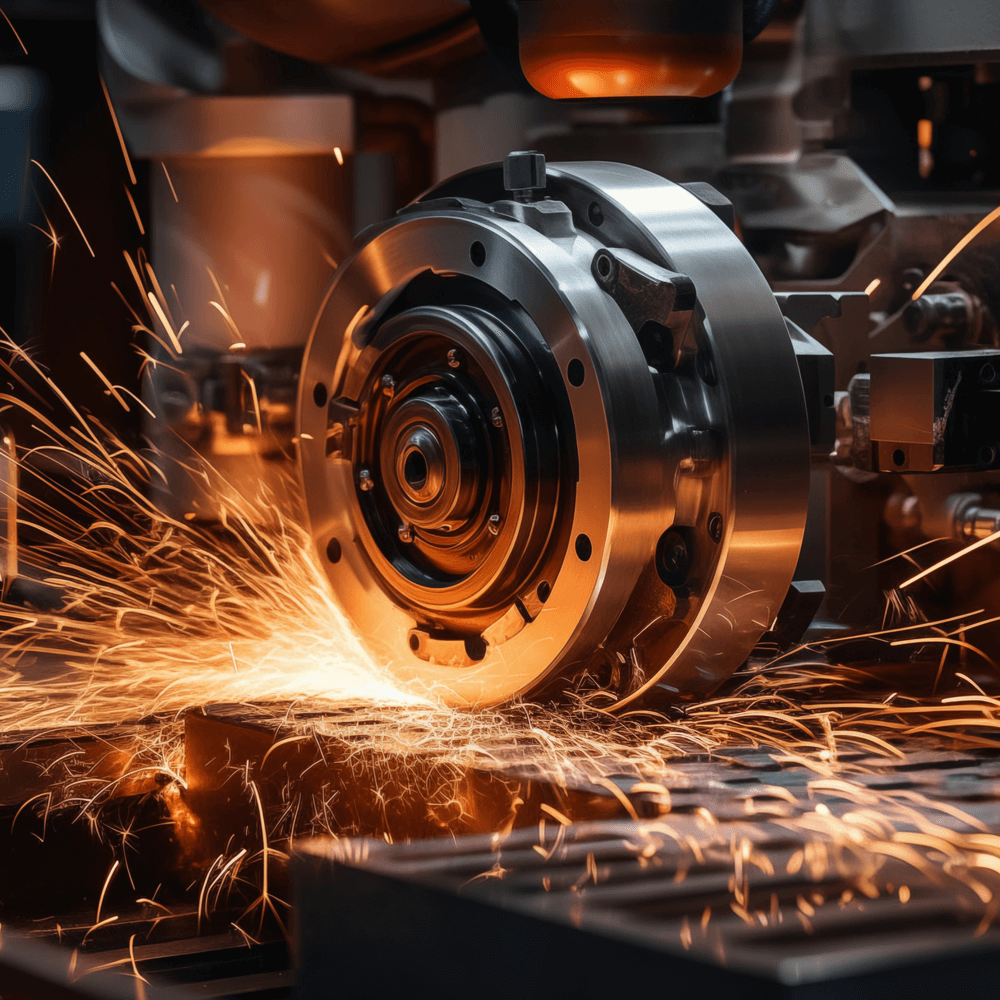

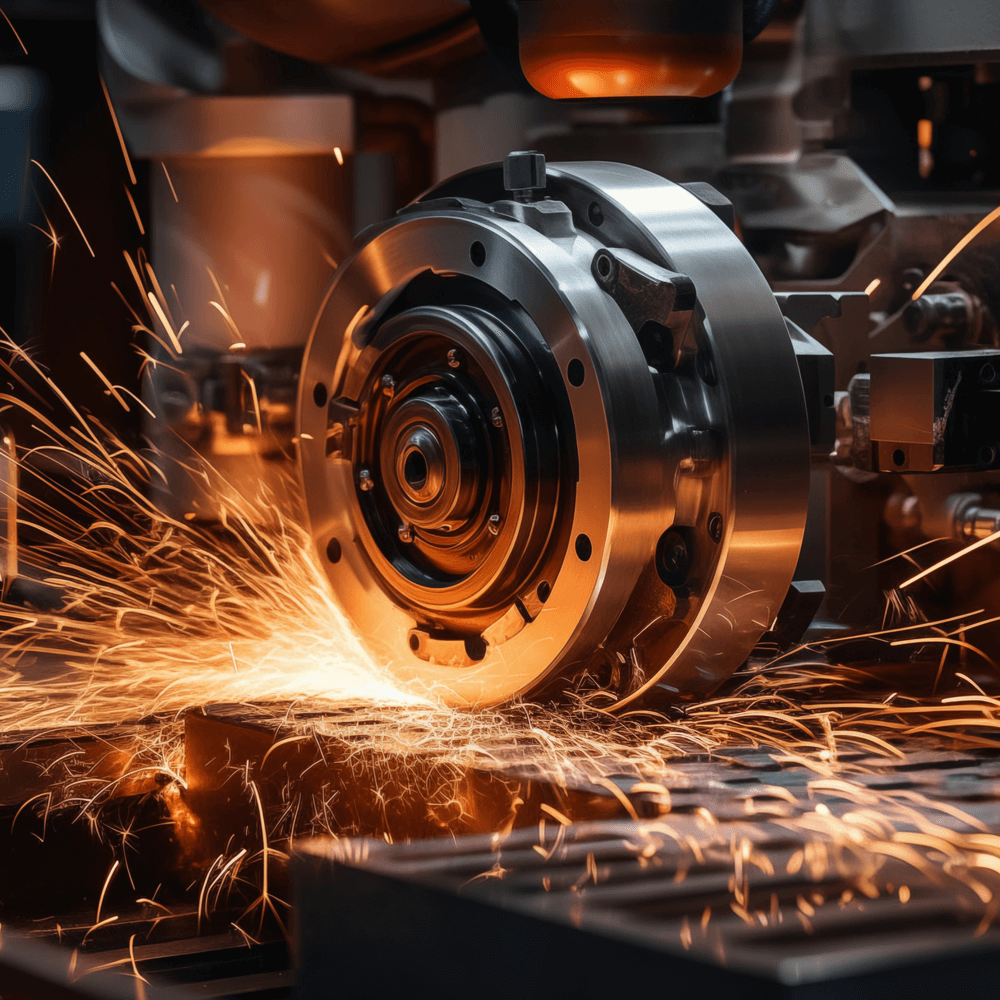

Your Partner in Precision Machining Services

Goodfellow specializes in providing precision machining solutions for exotic, hard to process and ceramics materials. Our expert team will review your drawing and look to provide a quote to match your requirements.

In any instance where we feel this is not possible or our engineers have an alternative solution for you, we will make these recommendations to you for your consideration.

We can offer:

- Specialist Machinable Ceramics Machining

- Specialist Exotic and Hard Materials Machining

- 5 axis CNC, turning, drilling, grinding and milling

- Full inspection and certification to your request

Goodfellow also offers a variety of polishing and lapping services dependent on your product requirements and specification:

- Polishing to a surface roughness less than 1micron

- Diamond Grinding

- Lapping

- Surface roughness measurements

Machined Materials (not limited to)

Alumina

Zirconia Toughened Alumina (ZTA)

Zirconia

Macor®

Shapal™

Sapphire

Aluminum Nitride

Tungsten Carbide

Silicon Carbide

Niobium*

Tantalum*

Molybdenum*

What's New