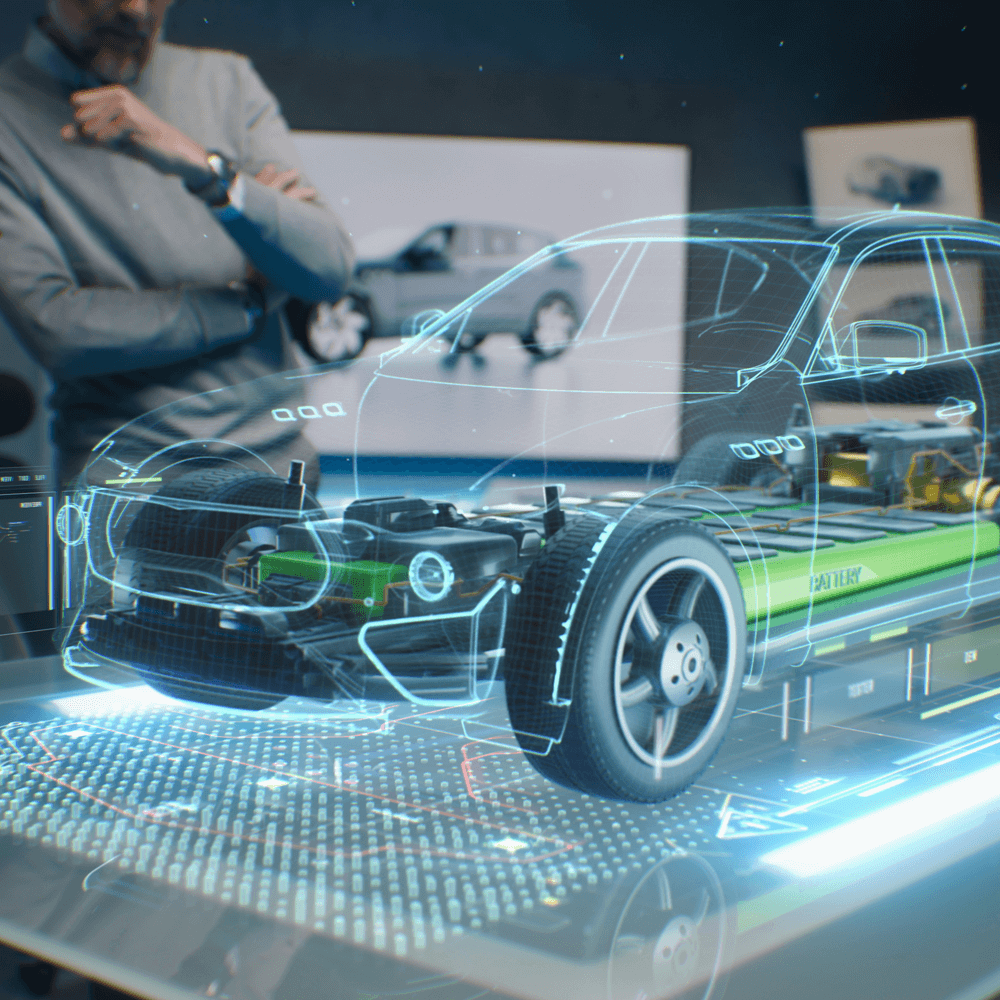

Your Partner for Automotive Innovation

The endless race for safer, more efficient and environmentally responsible transport is driving rapid technological advancements in the highly competitive industry.

The multitude of challenges facing this sector, including environmental and resource, alongside ever-changing consumer preferences, safety regulations and cutting-edge technologies, means innovative advanced materials are more critical than ever. Goodfellow is your partner to source high-quality advanced materials.

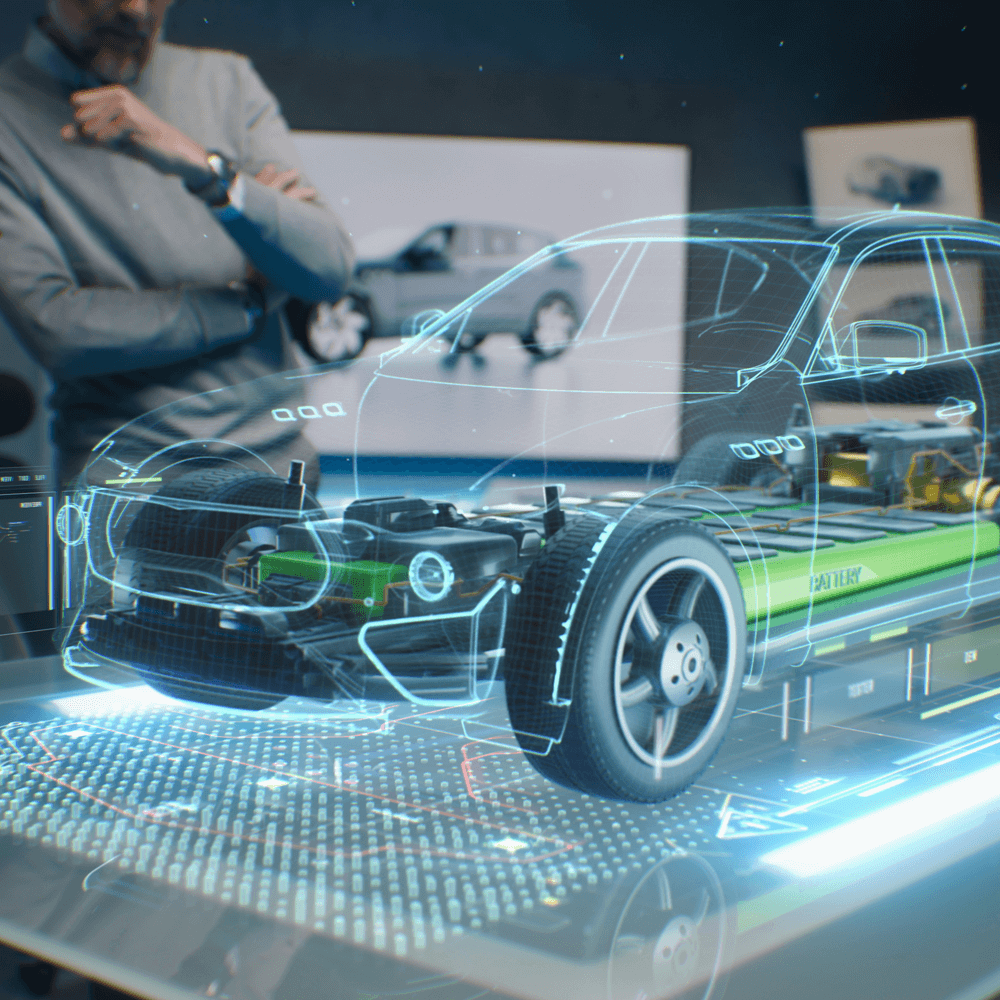

Helping You Choose the Right Materials

We understand the technical demands and challenges of the motorsport and high-end automotive industies require innovative and lightweight materials that do not compromise tensile strength and durability.

One of your key challenges is in achieving superior strength performance without the addition of weight. Typical materials used are alloys based on aluminum, magnesium and titanium. Composites and materials such as carbon fiber can be an excellent way of achieving excellent strength performance to ensure vehicle structural stability without the addition of the weight that steel components would add.

We provide high-quality metal foams that have the ability to absorb large amounts of mechanical energy for shock absorbers, for their protective properties in a crash or to help dampen vehicle sounds to reduce noise pollution.

If you need lightweight engine blocks, we supply aluminium and aluminum Alloys for structural components and other materials such as Titanium, proven for its higher tensile performance, or magnesium alloys, as a cost effective alternative.

We do 'hero' Graphene, as it has immense potential to revolutionize the automotive industry. It's known for weight reduction and enhanced properties, its application in breakthrough batteries and use in advanced electronics and sensors such as next-generation touch screens.

We can expect to see a growing number of vehicles utilizing graphene to achieve lighter weight, improved performance, and enhanced functionality. Goodfellow offers product customization capabilities via our expert Technical Solutions team.

Our Product Range

At Goodfellow, we offer a comprehensive range of high-purity materials relevant for your applications, including:

Challenge: A student team at the Instituto Technico at the University of Lisbon were creating an electric Formula 1 car and were experiencing issues with grounding and electrical interference due to the high operating voltage.

Solution: With the use of a highly lightweight and flexible copper mesh around the cockpit the team created something similar to a Faraday cage preventing any interferences, enabling grounding without the need for of a bulky and cumbersome wire network.

In addition, the team needed to stop an interference with the magnetic field in the motor but still ensure the necessary tensile performance. We supplied a titanium solution in the form of a 50mm, 1-meter-long circular bar, magnetically inert, able to withstand forces up to 20,000rpm. These materials passed the most stringent quality control tests, and played their part in the creation of an electrically driven motor capable of operating reliability at 150hp.

What's New