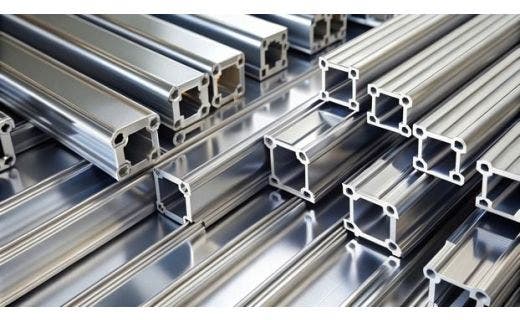

When your project demands more—higher strength, better machinability, or cutting-edge performance—the 6000, 7000, and 8000 series aluminum alloys deliver. These advanced materials are the backbone of modern engineering and research.

6000 Series: Aluminum-Magnesium-Silicon Alloys

- Main Alloying Element: Magnesium and silicon (forming magnesium silicide)

- Key Properties: Good strength, excellent corrosion resistance, great machinability, heat-treatable, versatile.

- Typical Uses: Construction, architecture, automotive parts, extrusions, structural components.

- Example: Aluminum 6061 is a go-to for engineers due to its balance of properties and ease of fabrication.

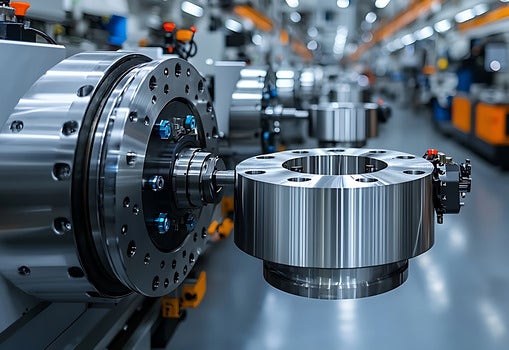

7000 Series: Aluminum-Zinc Alloys

- Main Alloying Element: Zinc

- Key Properties: Highest strength among aluminum alloys, excellent stress resistance, heat-treatable, but less corrosion resistant.

- Typical Uses: Aerospace, high-performance sporting equipment, automotive engineering, research requiring lightweight strength.

- Example: Aluminum 7075 is renowned for its use in aircraft and competitive sports gear.

8000 Series: Specialty Alloys

- Main Alloying Element: Varies (often iron, lithium, or other elements)

- Key Properties: Tailored for specific, high-tech applications; can offer high strength, formability, or unique properties.

- Typical Uses: Aerospace, advanced engineering, specialized research.

- Note: These alloys are often custom-sourced for unique requirements.

| Series | Main Alloying Element | Key Properties | Typical Uses |

| 6000 | Magnesium, Silicon | Versatile, strong, machinable | Construction, automotive |

| 7000 | Zinc | Highest strength, heat-treatable | Aerospace, sports equipment |

| 8000 | Varies | Specialized, custom properties | Aerospace, advanced research |

When to Choose These Alloys

- 6000 series: When you need a strong, versatile, and easy-to-machine material for general engineering.

- 7000 series: For maximum strength and performance, especially in weight-sensitive applications.

- 8000 series: For cutting-edge research or highly specialized engineering challenges.

The 6000, 7000, and 8000 series represent the pinnacle of aluminum alloy technology. By understanding their strengths and applications, you can harness their full potential for your next big project.