Microfluidics - An Evolving Technology Ready for Prime Time

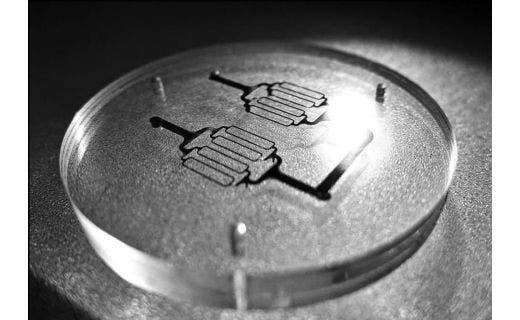

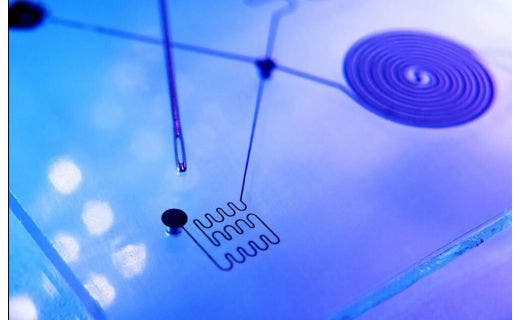

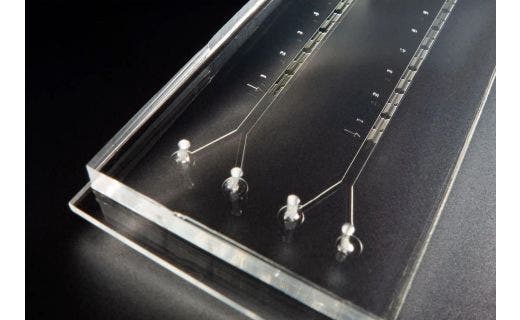

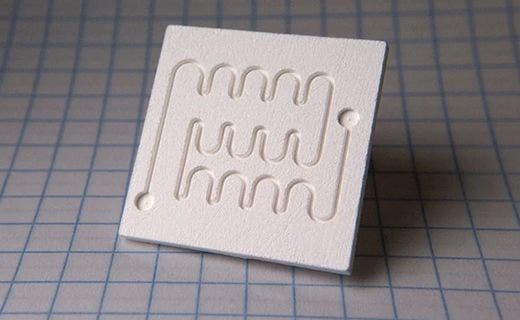

Microfluidics leverage semiconductor manufacturing processes to perform complex molecular biology tasks more quickly and cheaply than with traditional methods.

Microfluidics leverage semiconductor manufacturing processes to perform complex molecular biology tasks more quickly and cheaply than with traditional methods.

Plasma treatment, UV/Ozone treatment, chemical treatment, and surfactant treatment can be used to change the hydrophilicity of COC and improve its microfluidic performance.

Organ-on-a-chip platforms are microfluidic devices that allow scientists to study different organ-specific responses to drug treatments. As such, they offer a viable alternative to animal testing and could help speed up the drug approval process. Goodfellow is able to help create miniaturization solutions with UV laser and micro-CNC micromachining. Our prototype to high volume production capability also creates prototypes that are Designed for Manufacturing, ensuring fast time to market and immediate scalability.

Silicon wafers serve as a fundamental component in various technologies and, following our acquisition of Potomac Photonics, we're leading the charge in their manufacturing and optimization. This industry front-runner has made significant strides in refining techniques for precise feature creation and hole drilling in silicon wafers, which includes wafer dicing and detailed patterning for diverse applications.

Kapton polyimide is essential in many industries. Goodfellow division Potomac Photonics excels in laser micro machining Kapton, providing rapid contract manufacturing & full-scale production.

Rapid prototyping of new products is only successful if the rapid part of the term is met. With the internet available on multiple fast platforms, split-second delivery systems, and demands for instant gratification, companies in biotech, microfluidics, micro-electronics and consumer products can’t wait for a long prototyping process. They need prototypes, rapidly!

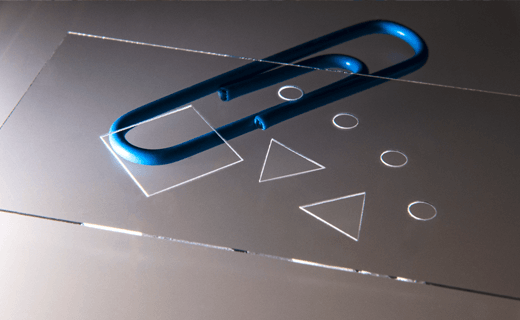

In the field of microfluidics, our expertise at Goodfellow sets a standard. We specialize in the art of laser drilling precise small holes in glass slides and coverslips, a critical capability for the fabrication of microfluidic devices. These devices play a pivotal role in various scientific, pharmaceutical, and medical diagnostics applications, demanding not just skill but a deep understanding of the intricate needs of microfluidics.

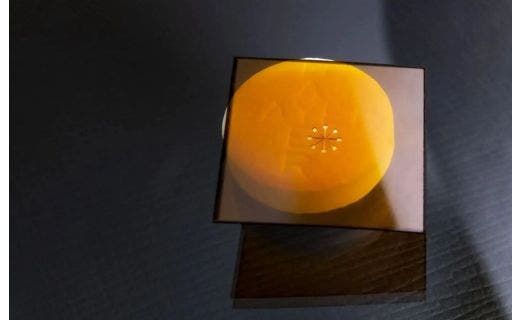

Solar cells are devices that convert energy from the sun into electricity without the use of any mechanical parts. Sunlight is made up of small energy particles known as photons, which can be absorbed into semiconductor material in a solar cell. Inside the solar cell, the energy from the photos is converted into electrical energy.

Materials that can withstand scorching temperatures, resist the harsh vacuum of space, and offer remarkable electrical properties. This isn't some futuristic invention; it describes ceramics, remarkably versatile materials that have been around for millennia. Today, ceramics are playing a crucial role in space exploration, showing how ancient materials can still be on the cutting edge of technological achievement.