A Guide to the Role of Alloys in Advanced Engineering

Alloys are mixtures of two or more elements in which at least one is a metal. Metal alloys are widely used in engineering because they can have a wide range of properties beyond those offered by the base metals they contain. Alloys used in engineering may be chosen for their hardness, electrical conductivity, strength, and corrosion resistance.

Understanding Alloys and Their Properties

The first step in creating a metal alloy is to select certain metals depending on their desired properties, such as strength or corrosion resistance. The metals are then melted together, mixed thoroughly, and cooled. From here, the alloy may be heat treated to bring out particular properties in the metal.

Alloys are generally stronger and more resistant to corrosion than the individual metals they contain. However, the reverse is often true about electrical conductivity: Metal alloys are often less conductive than the pure metals they contain.

Common Alloys Used in Engineering

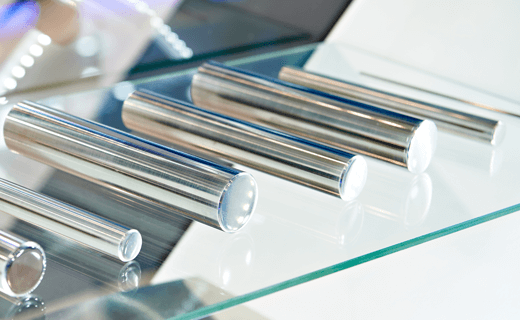

Steel alloys, which typically contain iron and carbon, are often used in engineering because of their hardness and strength. Additional elements like nickel, chromium, and manganese can be added to enhance specific properties. Stainless steel, which contains chromium that protects the alloy from corrosion, is widely used in construction, the automotive industry, and health care.

Favored for their corrosion resistance and lightweight nature, aluminum alloys often include elements like silicon, copper, and magnesium to improve their strength. They are easily welded into different shapes and have a long lifespan. Aluminum-copper alloys, known for their excellent strength, are commonly used in the automotive and aerospace industries.

Titanium alloys are known for their biocompatibility, strength, and high corrosion resistance. A particularly popular form of titanium alloy is Grade 5 titanium, which contains aluminum and vanadium. It has a very high strength-to-weight ratio and can stand up to high temperatures while still being weldable. This titanium alloy is used in aircraft components, medical implants, and marine equipment.

Renowned for their high corrosion resistance, oxidation resistance, and suitability for high-temperature environments, nickel alloys are also commonly used in engineering. They're especially useful for chemical processing and power generation equipment.

Advanced Engineering Applications

Alloys play a crucial role in a variety of engineering fields due to their enhanced properties, such as strength, durability, and corrosion resistance. In aerospace engineering, aluminum alloys are commonly used in aircraft structures for their high strength and light weight, while titanium alloys are favored for components like engines and landing gears. In automotive engineering, steel alloys are used for car bodies because of their strength and durability. Aluminum alloys are also employed in engine and wheel components due to their light weight and high strength. Biomedical engineering extensively uses titanium alloys in medical implants, owing to their high corrosion resistance and biocompatibility. And in civil engineering, steel alloys are widely used in the construction of buildings, bridges, and other structures, thanks to their strength and durability.

Additional Resources

- What Are Metal Alloys?

- Why Is Aluminum Used for Aircraft Sheet Metal?

- Understanding Aluminum and Aluminum Alloys

- Properties and Composition of Metal Alloys

- Alloys and Their Uses

- Alloys: Definition, Composition, Types, Properties, and Applications

- Metal Alloys for Research and Development

- Alloys: What They Are and What They Can Do

- Machine Learning Helping to Make New Alloys

- Guide to Metals and Alloys

- Types of Metal Alloys and Their Uses