Aluminum’s versatility comes from its ability to be alloyed with other elements, creating a range of materials with unique properties. The 1000–5000 series are the workhorses of the aluminum world, used in everything from scientific research to everyday products. Let’s break down what makes each series special.

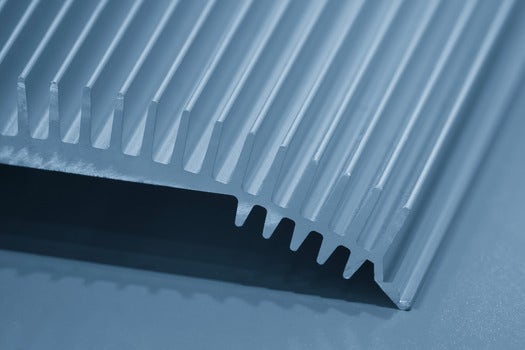

1000 Series: “Pure” Aluminum

- Main Alloying Element: None (99%+ aluminum)

- Key Properties: Exceptional corrosion resistance, high thermal and electrical conductivity, excellent workability, but low strength.

- Typical Uses: Laboratory electrodes, capacitors, heat sinks, solar reflectors, and food packaging.

- Note: Its high purity makes it ideal for scientific experiments and applications where contamination must be minimized.

2000 Series: Aluminum-Copper Alloys

- Main Alloying Element: Copper

- Key Properties: High strength-to-weight ratio, excellent machinability, heat-treatable, but lower corrosion resistance.

- Typical Uses: Aerospace components, high-performance engineering parts, and structural applications.

- Example: Aluminum 2024 is a favorite in aircraft structures.

3000 Series: Aluminum-Manganese Alloys

- Main Alloying Element: Manganese

- Key Properties: Moderate strength, good corrosion resistance, excellent workability, non-heat-treatable.

- Typical Uses: Heat exchangers, storage tanks, kitchenware, and medical instruments.

- Example: Aluminum 3003 is widely used for its balance of strength and flexibility.

4000 Series: Aluminum-Silicon Alloys

- Main Alloying Element: Silicon

- Key Properties: Lower melting point, good ductility, high fluidity, good thermal and electrical conductivity.

- Typical Uses: Automotive parts, brazing alloys, microwave circuit covers.

- Example: Aluminum 4047 is popular for welding and brazing.

5000 Series: Aluminum-Magnesium Alloys

- Main Alloying Element: Magnesium

- Key Properties: Excellent corrosion resistance (especially in saltwater), good strength among non-heat-treatable alloys, weldable.

- Typical Uses: Marine equipment, cryogenic tanks, pressure vessels, and aircraft components.

- Example: 5052 (workability and corrosion resistance), 5083 (strength and durability).

| Series | Main Alloying Element | Key Properties | Typical Uses |

| 1000 | NONE | High conductivity, corrosion resistance, low strength | Lab electrodes, heat sinks |

| 2000 | Copper (Cu) | High strength, machinable, heat-treatable | Aerospace, structural |

| 3000 | Manganese (Mn) | Moderate strength, corrosion resistance | Heat exchangers, tanks |

| 4000 | Silicon (Si) | Low melting point, ductile | Automotive, brazing |

| 5000 | Magnesium (Mg) | Corrosion resistance, weldable | Marine, cryogenics |

Choosing the Right Series

- For purity and conductivity: 1000 series

- For strength: 2000 series

- For general-purpose and corrosion resistance: 3000 or 5000 series

- For specialized joining or casting: 4000 series