Perfect for Machining of Ceramics

Shapal Hi-M Soft is a composite of aluminum nitride (AlN) and boron nitride (BN), mixed and sintered together to create a dense ceramic material. The unique composition of Shapal Hi-M Soft and the conditions under which it is produced result in lamellar crystal particles. These crystallites help prevent the surface cracks and fractures often associated with the machining of ceramics.

Product Benefits

Superior Machinability:

Allowing it to be shaped into complex, high-precision forms using a variety of techniques such as drilling, turning, and milling. It also provides an effective seal in vacuum conditions.

High Thermal Conductivity:

It is approximately four times greater than that of alumina (aluminum oxide), and it boasts of:

- High mechanical strength, flexural strength of 30kg/mm2 which is comparable to that of alumina

- Transparency to infrared light allows visible infra-red light to pass through easily

Remarkable Electrical Characteristics:

It provides excellent insulation resistance and exhibits a low dielectric loss factor and a small dielectric constant.

High Corrosion Resistance:

It does not react with molten metals. Even at high temperatures, Shapal Hi-M Soft maintains its purity, ensuring that molten metal remains uncontaminated

Utilize the Breadth of Machining Methods

Shapal Hi-M Soft is manufactured as a hot-pressed large sheet or billet (the largest being approximately 305mm x 305mm x 84mm). This sheet can be easily machined into complex shapes and sizes, while holding tight tolerances.

Goodfellow offers Shapal Hi-M Soft in different forms such as:

- Shapal Hi-M Soft Bars

- Shapal Hi-M Soft Tubes

- Shapal Hi-M Soft Rods

- Shapal Hi-M Soft Disks

- Shapal Hi-M Soft Sheets

- Shapal Hi-M Soft Customized Components can be produced with specified surface finishes and tolerances

How SHAPAL Hi-M Soft can be Applied

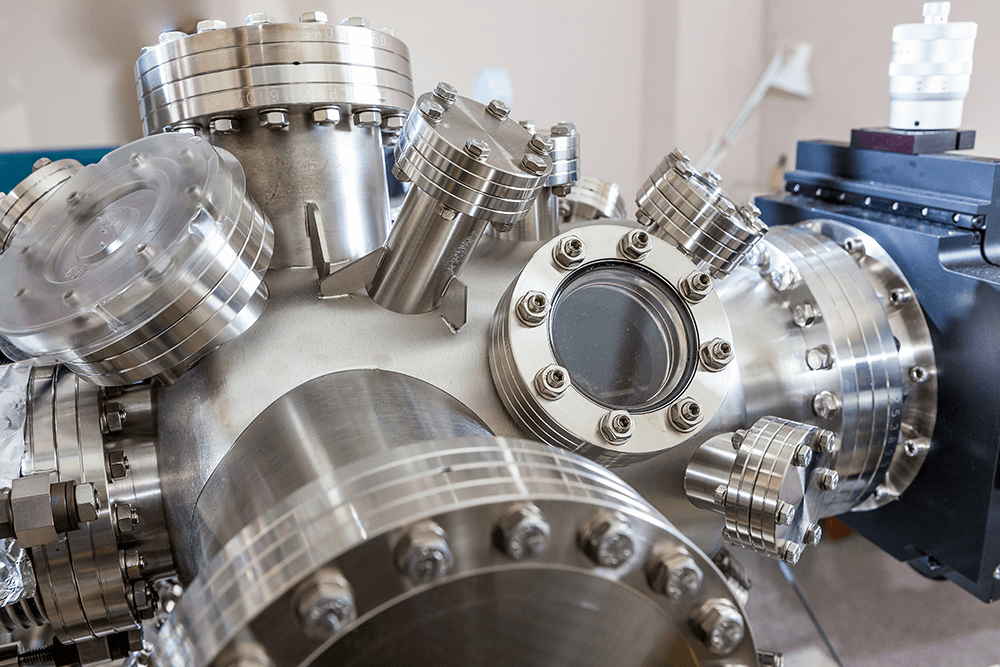

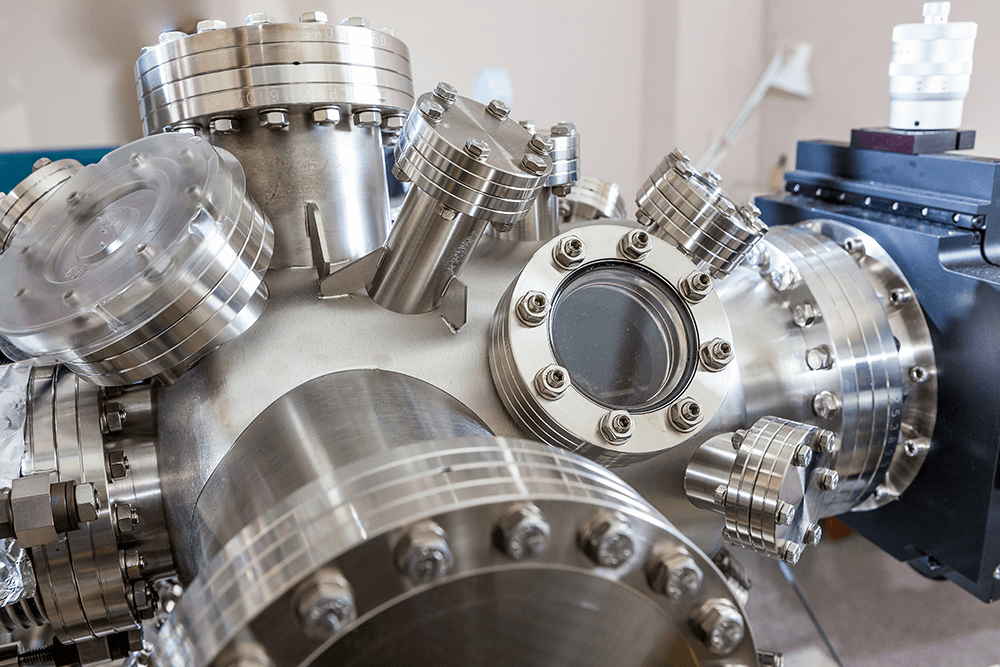

Vacuum Parts or Components

Shapal Hi-M Soft’s excellent sealing ability being a non-porous material with non-outgassing behavior makes it ideal for manufacturing parts or components that operate in vacuum conditions. This includes parts in vacuum chambers and vacuum processing equipment where maintaining a high-quality vacuum is crucial.

Electronic components

In electronics, managing heat is a critical concern. Shapal Hi-M Soft, with its high thermal conductivity, is an excellent material for electronic components where heat dissipation is required, such as in power electronics and high-frequency devices.

Refractory Parts

Shapal Hi-M Soft’s high mechanical strength and thermal stability make it suitable for refractory parts such as protective tubes. These tubes can be used in high-temperature environments, such as furnaces, without deforming or melting.

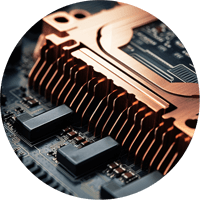

Heat Sinks

Heat sinks are used to dissipate heat from electronic devices and prevent overheating. Shapal Hi-M Soft’s high thermal conductivity makes it an excellent material for heat sinks, ensuring efficient heat transfer and cooling of devices.

Crucibles for Vacuum Deposition

In vacuum deposition processes, materials are deposited in a vacuum environment. Shapal Hi-M Soft can be used to make crucibles for these processes due to its high temperature stability, non-outgassing behaviors and non-reactivity with molten metals.

High Temperature Nozzle

Nozzles operating under high-temperature conditions require materials that can withstand these temperatures without degrading. Shapal Hi-M Soft, with its high-temperature properties, is ideal for such applications.

Components and Parts

In applications where dimensional stability over a range of temperatures is required, Shapal Hi-M Soft is an excellent choice. Its low coefficient of thermal expansion means it experiences minimal expansion or contraction with temperature changes, making it ideal for precision components.

What's New