The Value of Our Recent Partnerships for Your Business

How Suisse Technology Partners, BAS, and Potomac are Expanding Goodfellow’s Capabilities for You

At Goodfellow, innovation and customer service have always driven our mission. As we continue to grow, we’re proud to welcome three cutting-edge companies into Goodfellow: Suisse Technology Partners, BAS, and Potomac. These partnerships not only expand our portfolio, but significantly enhance our ability to support the ever-changing needs of modern R&D and manufacturing. From faster development times to new technical expertise, this collaboration brings tangible benefits to our customers.

To mark this new chapter, we’ve updated our look to reflect who we are today—a united group of forward-thinking companies working together to push the boundaries of materials science and advanced manufacturing.

1. Introducing Our New Partners

Each new member of the Goodfellow family strengthens our foundation with unique, highly specialized knowledge:

Suisse Technology Partners

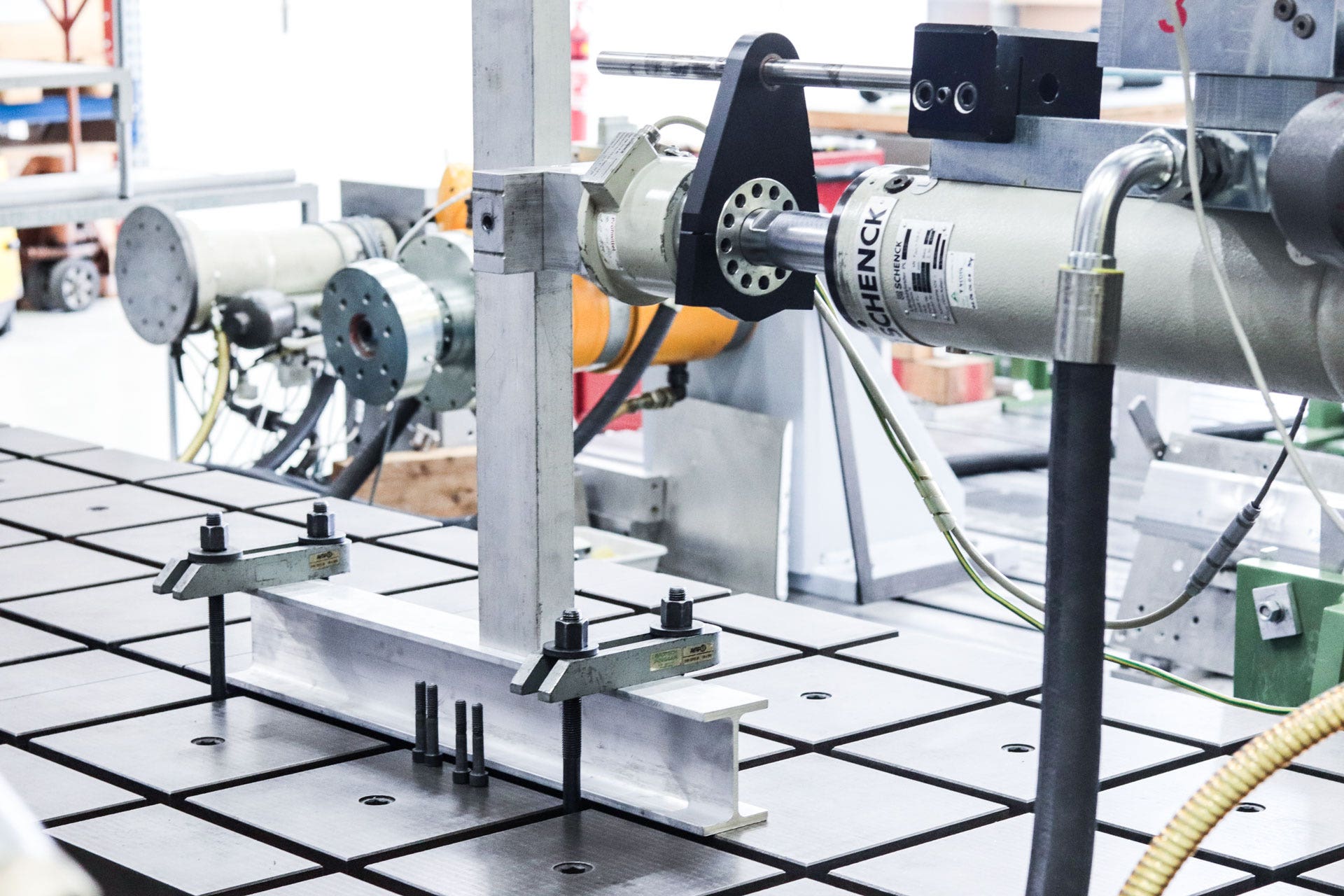

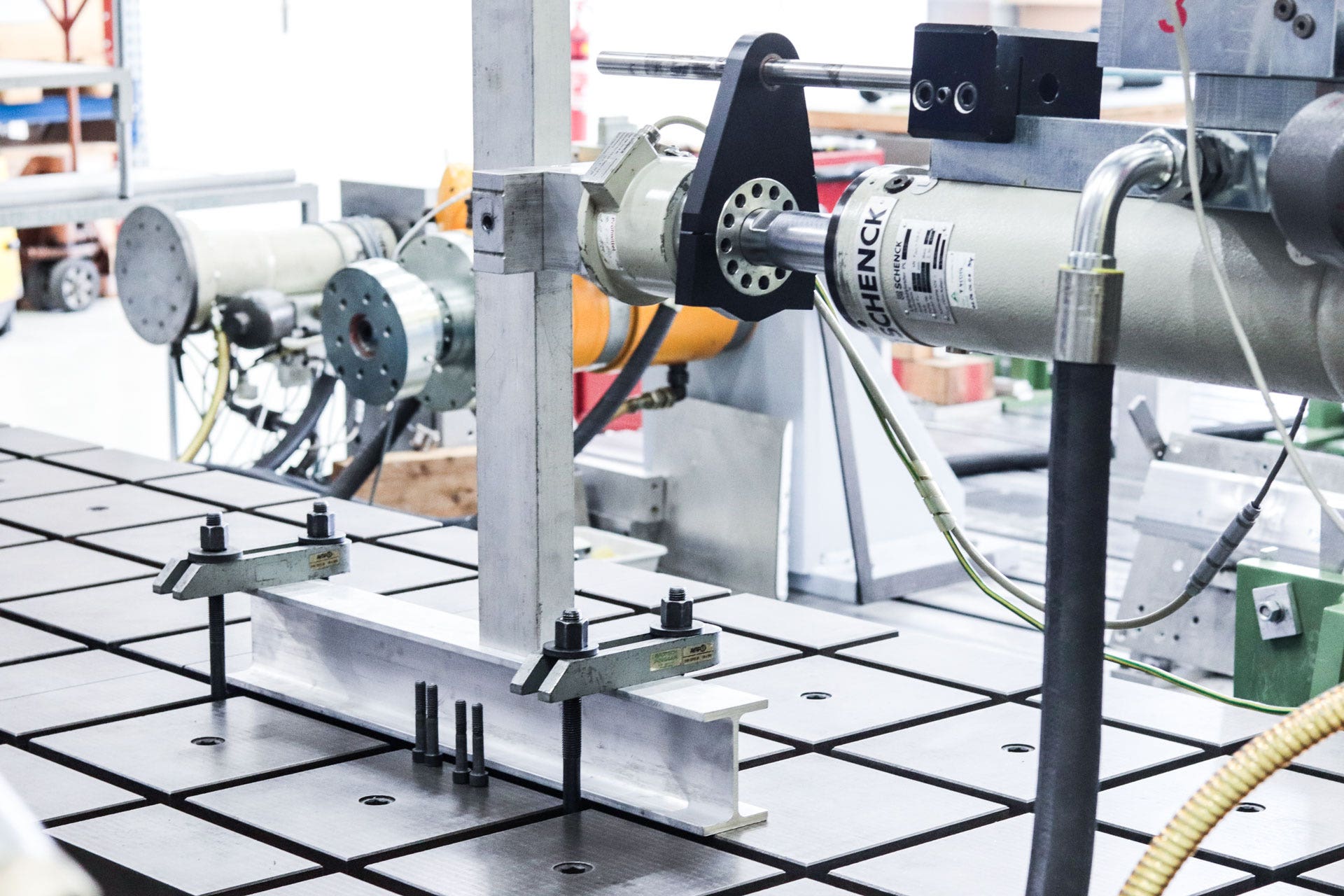

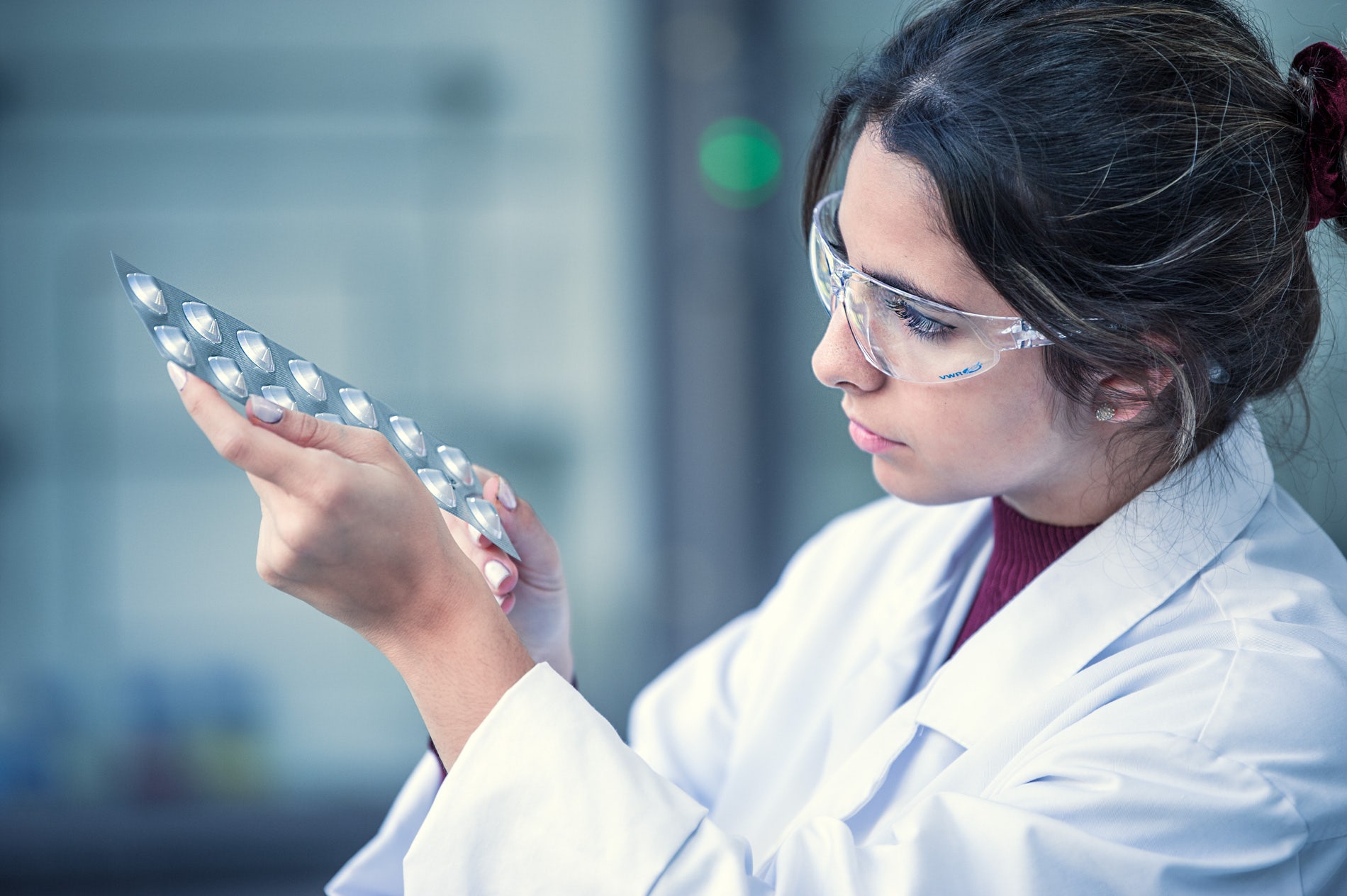

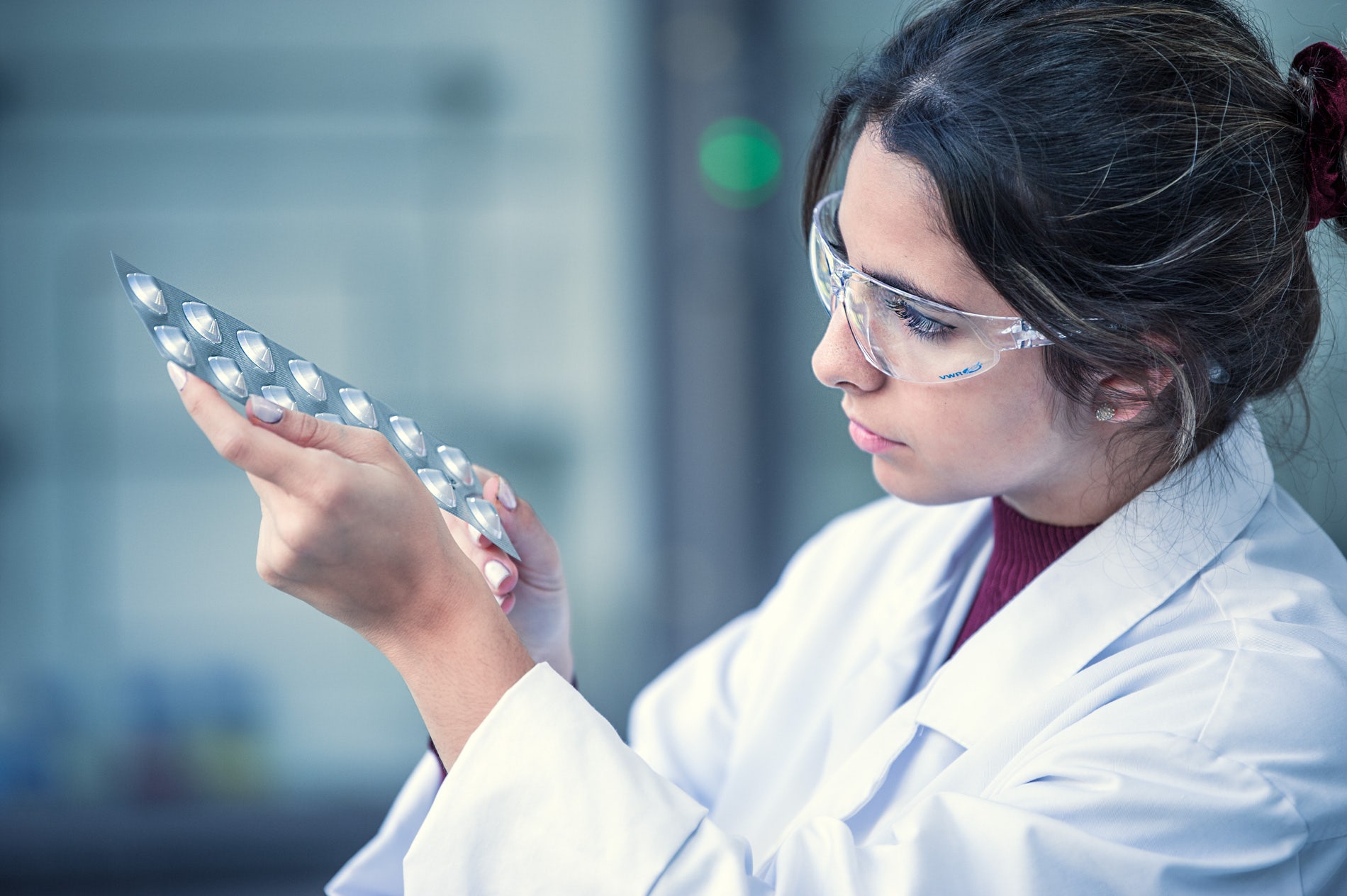

Suisse Technology Partners is a Swiss competence center for material-based solutions and analytics. It is an independent, accredited provider specializing in the development, production and certification of certified reference materials, as well as advanced materials testing and aluminum surface technologies. With decades of expertise in metals, polymers, ceramics, and composites, they offer precise diagnostics, in-depth failure analysis, and expert consulting for complex technical challenges. Key services include materials consulting, analysis and testing, environmental simulation, as well as a dedicated galvanic lab. Further to this, full scale component testing for validation and release is provided in an accredited in-house laboratory. Suisse Technology Partners is also a key resource for the pharmaceutical sector, supporting packaging development, analytics for validation, and compliance. Their strong ties to both industry and academic institutions position them as a reliable, integrated partner for innovative solutions.

Bureau of Analysed Samples

BAS (Bureau of Analysed Samples) has over 85 years of expertise in the production and distribution of high-quality Certified Reference Materials (CRMs) for the iron and steel industry. With a comprehensive range of BCS- and EURONORM-certified reference materials in chip and powder form, BAS enables accurate chemical analysis for a wide range of materials, including steels, cast irons, non-ferrous alloys, ores, and ceramics. Additionally, SS-CRMs in solid form are available from BAS to support spectroscopic analysis, suitable for most steel and cast-iron types, together with Reference Materials (RMs) and setting-up samples. They also offer analytical services, including classical methods and instrumental techniques like AAS and ICP-OES. As an ISO 17034:2016 accredited company, BAS ensures the highest standards in reference material production. Their commitment to precision and traceability guarantees consistent, reliable testing with full regulatory compliance.

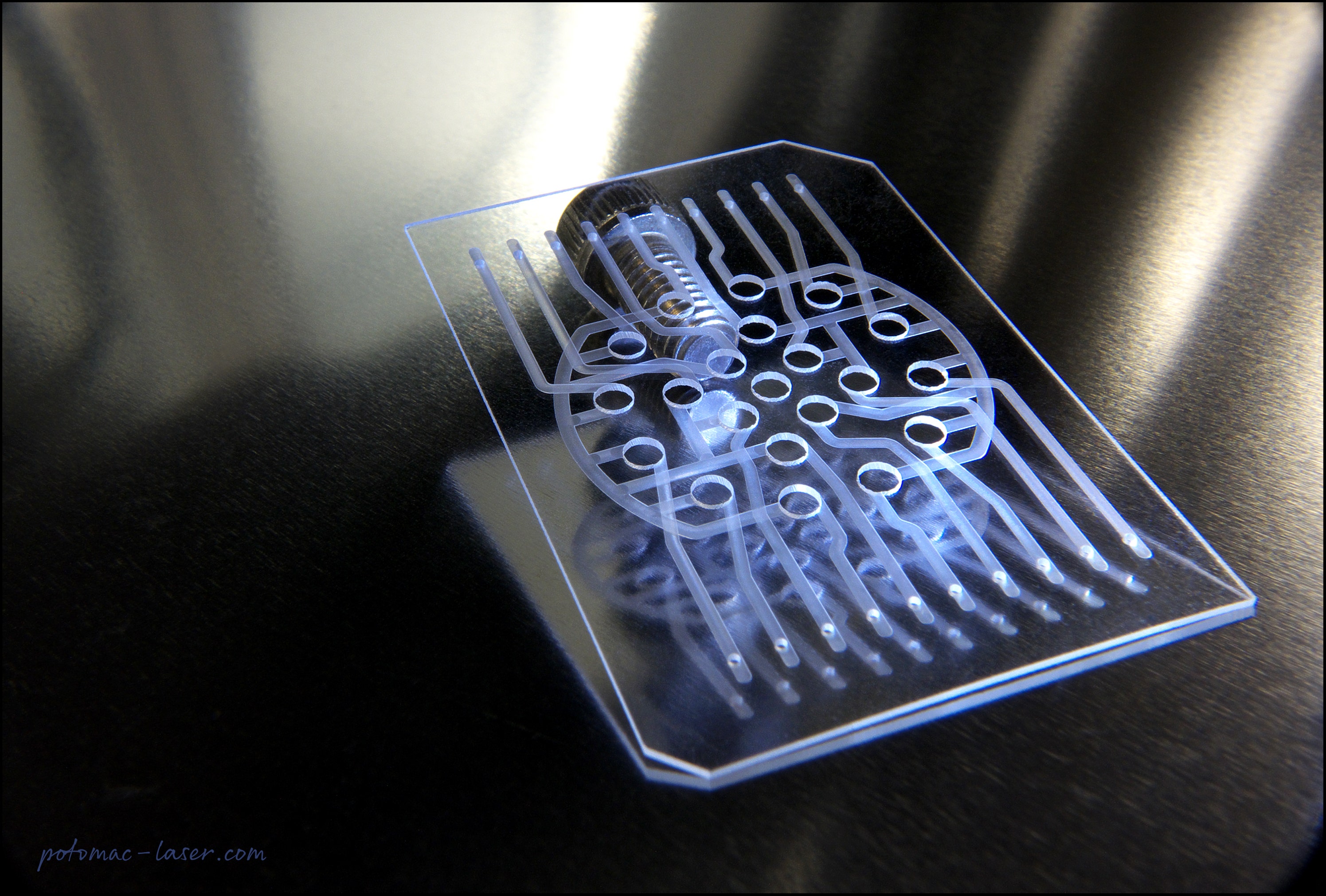

Potomac Photonics

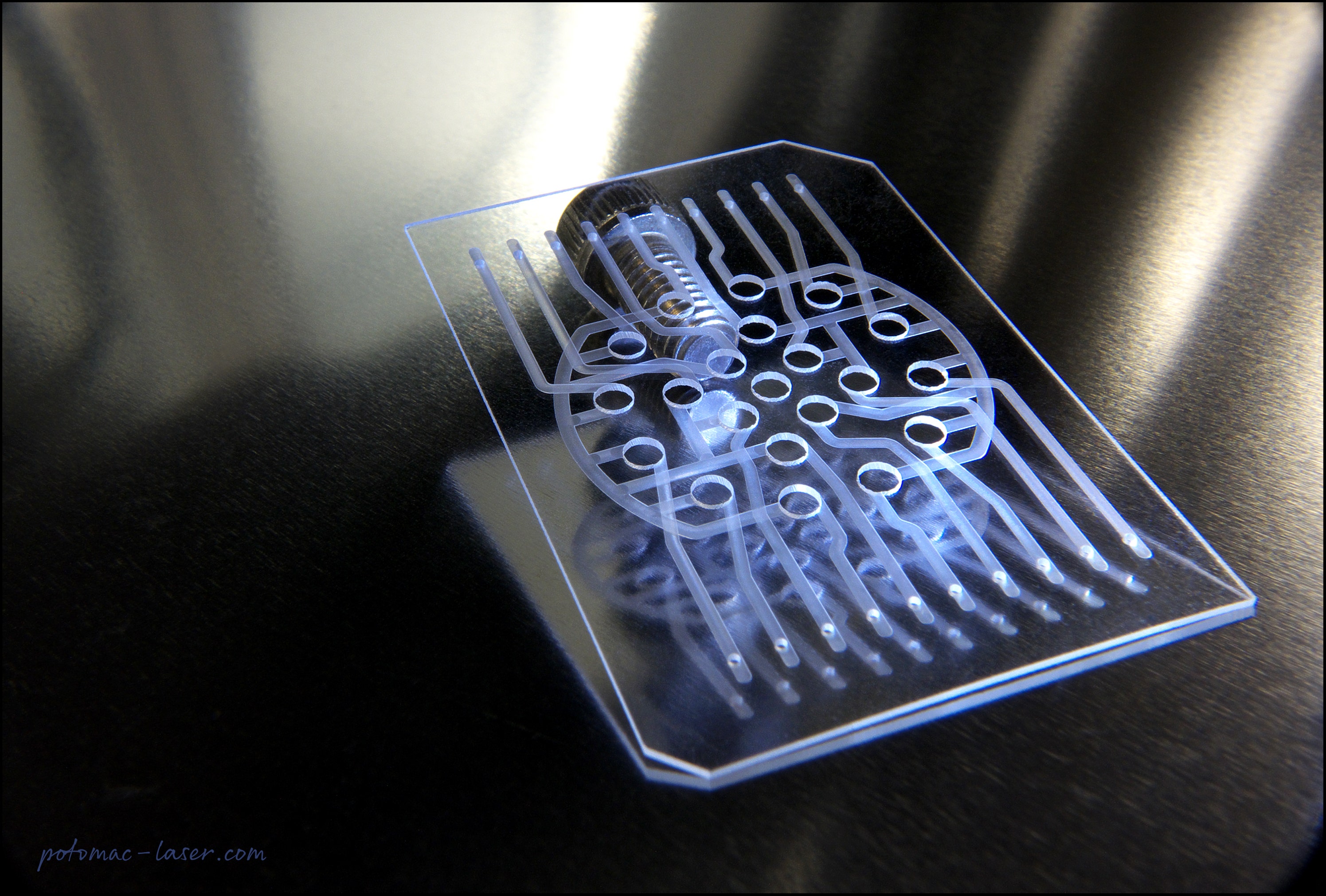

Potomac adds advanced micromachining solutions into the fold. A pioneer in digital microfabrication with over 40 years of experience, Potomac offers a wide range of services, from rapid prototyping to full-scale production of precision components. Their capabilities include laser micromachining, micro-CNC machining, 3D printing, hot embossing, and bonding—enabling high-precision fabrication across a variety of materials such as polymers, metals, ceramics, and glass, often at micron-scale resolution. This broad technical offering supports both commercial and government clients with an end-to-end approach that ensures rapid turnaround without compromising quality or precision. Renowned for driving innovation in biomedical fields, Potomac plays a vital role in emerging applications like cell therapy, cancer diagnostics, and lab-on-a-chip technologies.

With these new additions—and our own material offering of 170,000 standard and custom materials—we’re equipped to tackle your toughest challenges faster, smarter, and with greater precision.

2. End-to-End Solutions, All In One Place

Thanks to our expanded network, a fully integrated process is now within reach—from initial research and material selection to precision manufacturing, advanced surface engineering, and in-depth analytical testing. This streamlined approach ensures that customers can effortlessly move from concept to prototype to full-scale production with a single reliable partner:

Extensive Product Offering

An extensive library of 170,000+ materials offers unmatched flexibility for a wide range of research, development, and production needs. Complementing this is a portfolio of more than 80,000 CRMs, covering over 600 different alloys. Many items are stocked for immediate dispatch, and our global supplier network guarantees fast delivery for non-stock materials.

Full-Spectrum Testing & Analytical Services

We now offer an extensive range of mechanical testing services, tensile, compression, and bending tests, as well as high-cycle and low-cycle fatigue, creep, and rotating bending tests. Our chemical analysis capabilities cover elemental analysis, chromatography, and wet chemical methods, along with method development, validation, and transfer. A core strength is our ability to create and implement bespoke testing methods, tailored to the specific needs of each customer. Upon request, we can also certify Goodfellow materials.

Product Development, Optimization, and Characterization

Our product and process optimization department supports customers in making their products and processes more efficient, safer and more powerful. Drawing on in-depth expertise in materials science and engineering, combined with cutting-edge analytical methods, we identify the most suitable materials for specific applications, troubleshoot performance concerns and develop solutions – ensuring each one is precisely tailored to our customers’ specific requirements. In this, we take an interdisciplinary approach, addressing challenges from multiple viewpoints to ensure holistic outcomes.

In the field of pharmaceutical packaging, we develop, optimize, analyze, and test packaging solutions to enhance barrier properties, predict shelf life, and ensure the stability of your products.

State-of-the-Art In-House Facilities

A variety of in-house laboratories and highly specialized machinery enables seamless support from development through to production. Proprietary systems and custom-built equipment provide the flexibility to rapidly adapt to unique project requirements, ensuring efficient transitions at each phase. In many cases, manufacturing solutions are designed and configured for specific applications—as demonstrated in this case study on the ramp-up of complex semiconductor components.

Leveraging Our Network to Deliver More

With industry memberships and an extensive network across various sectors, including partnerships with trade associations, universities, and strategic partners, we can continually expand our expertise. In addition to our own broad product and service offerings, this extended ecosystem enables us to meet specialized customer needs and deliver complex, integrated services from a single point of contact.

A Multidisciplinary Team

Our trained team includes experts in materials science, chemical research, laboratory analysis, mechanical and process engineering, production engineering, software development, 3D design, micromanufacturing, and quality assurance. This know-how allows us to meet complex customer needs with precision, deliver innovative solutions, and ensure high-quality, compliant, and tailored services for each project.

3. More Innovation Power, Accelerated Timelines

With a strengthened foundation of innovation, Goodfellow has evolved into a more agile and responsive partner capable of accelerating timelines and adapting swiftly to dynamic project demands. By combining world-class materials with advanced capabilities in microfabrication, testing, and surface engineering, we're eliminating the need for multiple external vendors and simplifying traditionally fragmented workflows.

A standout example of this synergy is Potomac's recent collaboration with the University of Michigan. In this project, our ultra-thin 12.5 µm aluminum foil was essential to the creation of a breakthrough microfabricated component. Potomac produced a precision part featuring 7-micron-wide struts—thinner than a human hair—demonstrating how critical high-performance materials are for achieving such extreme tolerances. Because the material and the manufacturing expertise were available within one team, the entire process was faster, more cohesive, and exceptionally precise.

4. Local Expertise, Global Reach

5. New Possibilities in Emerging Technologies

Our expanded capabilities are unlocking new opportunities across some of the most innovative and fast-evolving sectors. With a focus on providing cutting-edge materials and expert services, we’re enabling advancements in:

- Medical devices and biomedical applications

- Aerospace and defence materials

- Advanced coatings and surface treatments

- Electronics, microfluidics, and sensor technologies

- Pharmaceutical packaging

- Industrial Applications

- Certified Reference Materials (CRMs) and testing

If your work lies within any of these transformative industries, we provide tailored solutions as well as comprehensive support to accelerate your R&D and help bring your innovations to market faster.

6. Assured Quality Through Accreditation

We maintain a comprehensive set of certifications to ensure the highest standards across our diverse product and service offerings:

Product Quality & Manufacturing

- ISO 9001

- ISO 13485

- Good Manufacturing Practice (GMP)

Testing & Laboratory Services

- ISO/IEC 17025

Certified Reference Materials (CRMs)

- ISO 17034

Regulatory Compliance

- FDA Registration

- Controlled Substances License (authorized to handle controlled substances per Swiss regulations)

Conclusion: A Future-Focused Approach

With the addition of Suisse Technology Partners, BAS, and Potomac to the Goodfellow family, we are better equipped than ever to offer you a full range of integrated, innovation-driven solutions. These partnerships provide you with unparalleled access to new technologies, expert insights, and custom-tailored services that are essential for navigating today’s dynamic market.