Key Benefits for Glass Manufacturing

Having access to Goodfellow's specialist glass materials provides you with unique properties tailored for specific applications:

- Optical glass: for highlight transmittance, refractive indices and minimal dispersion

- Specialist high purity glasses for low electrical conductivity and thermal stability in electronics and optoelectronics. Other types include high-strength, chemical-resistant glass, and glass with low thermal expansion coefficients

Our Range of Products for Glass Applications

Glass Melting and Processing

High-purity silica powders: Used as a primary raw material for various glass compositions, offering high purity and consistent quality for predictable melting behavior

Fluxing agents: Materials like borates, fluorides, and carbonates, added to the glass melt to lower the melting temperature and improve workability

Coloring agents: Metal oxides or other compounds incorporated into the glass melt to achieve specific colors or optical properties

Fining agents: Materials that promote the removal of gas bubbles from the molten glass, leading to a clear and defect-free final product

Specialty Materials for Glass Applications

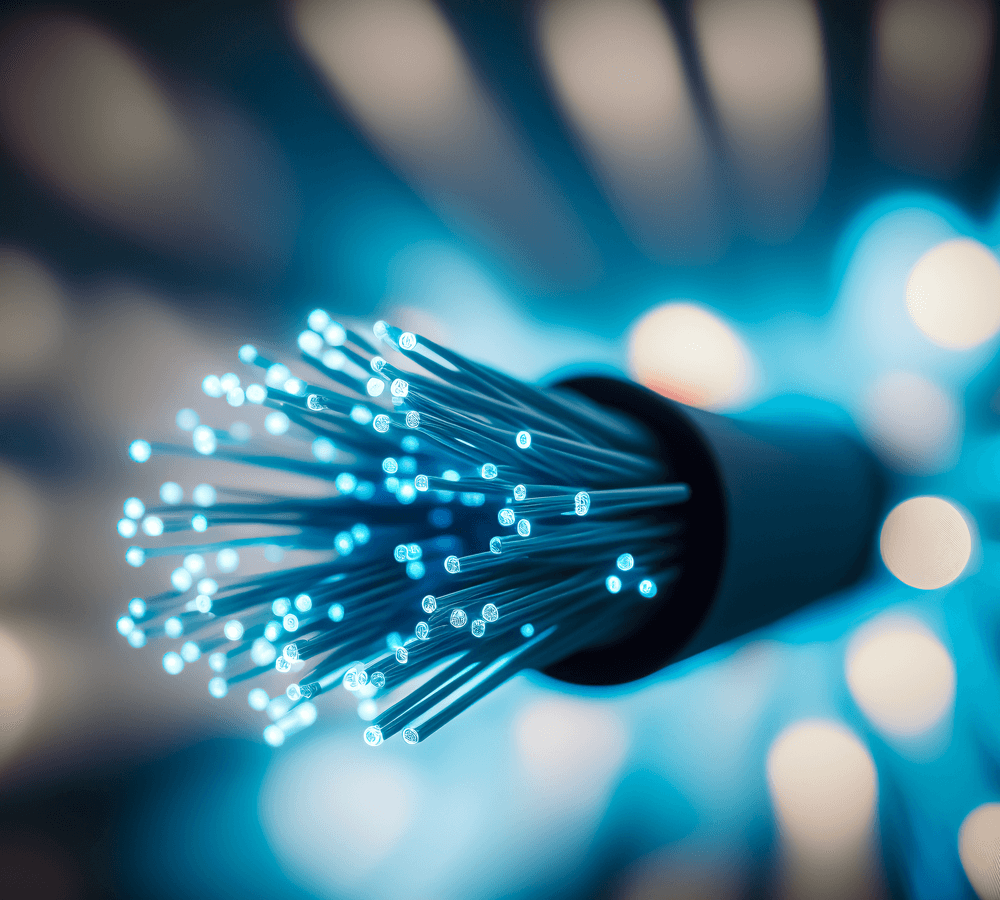

Conductive glasses: Doped with specific elements to exhibit electrical conductivity, enabling applications like touchscreens and transparent electrodes

Sealing glasses: Form strong bonds with other materials like metals or ceramics, crucial for creating hermetic seals in electronic packaging and other applications

Low-expansion glasses: Exhibit minimal dimensional changes with temperature fluctuations, making them suitable for applications requiring high dimensional stability like telescope mirrors and scientific instruments

Materials for Glass Shaping and Fabrication

Glass frit: Crushed or granulated glass used for various applications like enameling, glassblowing, and investment casting, offering precise control over material distribution

Glass fibers: Strands of glass used for various purposes like insulation, reinforcement composites, and optical applications. Goodfellow offers different fiber diameters and compositions

Glass rods and tubes: Solid or hollow glass sections used for crafting specialized components, scientific equipment, and decorative objects

Applications

Aerospace

Glass and glass components play a key role in the aerospace sector. They play an important part in protecting electronics, sensors, and navigation equipment from the harsh pressure and temperature environments the sector encounters, where reliability and performance are paramount.

Medical

There are many uses of glass and glass components in medical applications. From optical windows used in laparoscopic devices for keyhole surgery to X-ray transmission windows in radiation devices, glass plays an important role in the ever-evolving sector.

Optics

The transparency, durability, and precision of glass and glass windows makes it an ideal material for use in optical devices. Analytical equipment, measuring instruments, microscopes all utilize glass in some ways, as do more personal devices such as smart phones and cameras, where quality and clarity of image as become ever more important.

High Vacuum

Vacuum sight glasses are vital for inspection, monitoring and measurement of substances or components in high vacuum compartments. Particularly important in gas and oil industry, the low thermal expansion and high strength of glass windows, allow for bonding to metal housing without breaking vacuum.

What's New